Introduction to Protection Screens and Unloading Platforms in High-Rise Construction

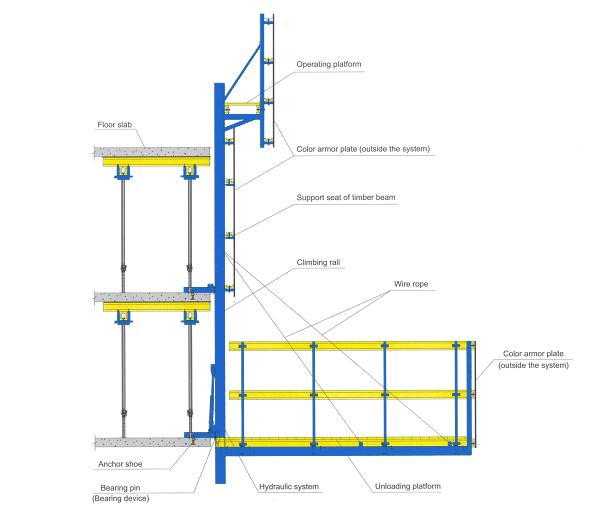

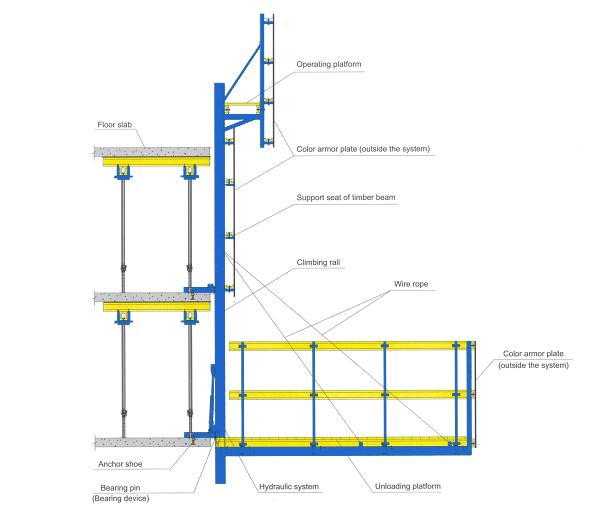

In the realm of high-rise building construction, the protection screen plays a pivotal role in ensuring safety. Comprising of rails and a hydraulic lifting system, this self-climbing system eliminates the need for a crane. Perhaps most importantly, it effectively encloses the entire pouring area, spanning across three floors simultaneously. This comprehensive coverage serves as a formidable barrier against falling from height (FFH) accidents, ultimately safeguarding the construction site.

To further enhance efficiency, the protection screen can be equipped with unloading platforms. Once the slab has been poured, the formwork and scaffolding can be seamlessly transported to these platforms. Subsequently, a tower crane deftly lifts the materials to the upper levels, expediting the progress of subsequent tasks. This integration of unloading platforms significantly optimizes resource utilization, reduces labor requirements, and accelerates construction timelines.

The protection screen represents an advanced and cutting-edge safety system, tailored to meet the demands of safety and modern practices on construction sites. As a testament to its effectiveness, it has been widely adopted in high-rise tower construction projects worldwide.

Beyond its safety merits, the exterior armor plate of the protection screen serves a dual purpose as an advertising platform for contractors. This additional feature not only ensures safety but also presents an opportunity for contractors to promote their brand and showcase their work to a wider audience.

In conclusion, the protection screen and its incorporation of unloading platforms revolutionize safety and efficiency in high-rise construction. With its ability to mitigate the risks associated with FFH accidents, improve resource management, and serve as an advertising board, it remains an indispensable component in the construction of tall buildings.

Structure diagram

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe