1. Project Introduction

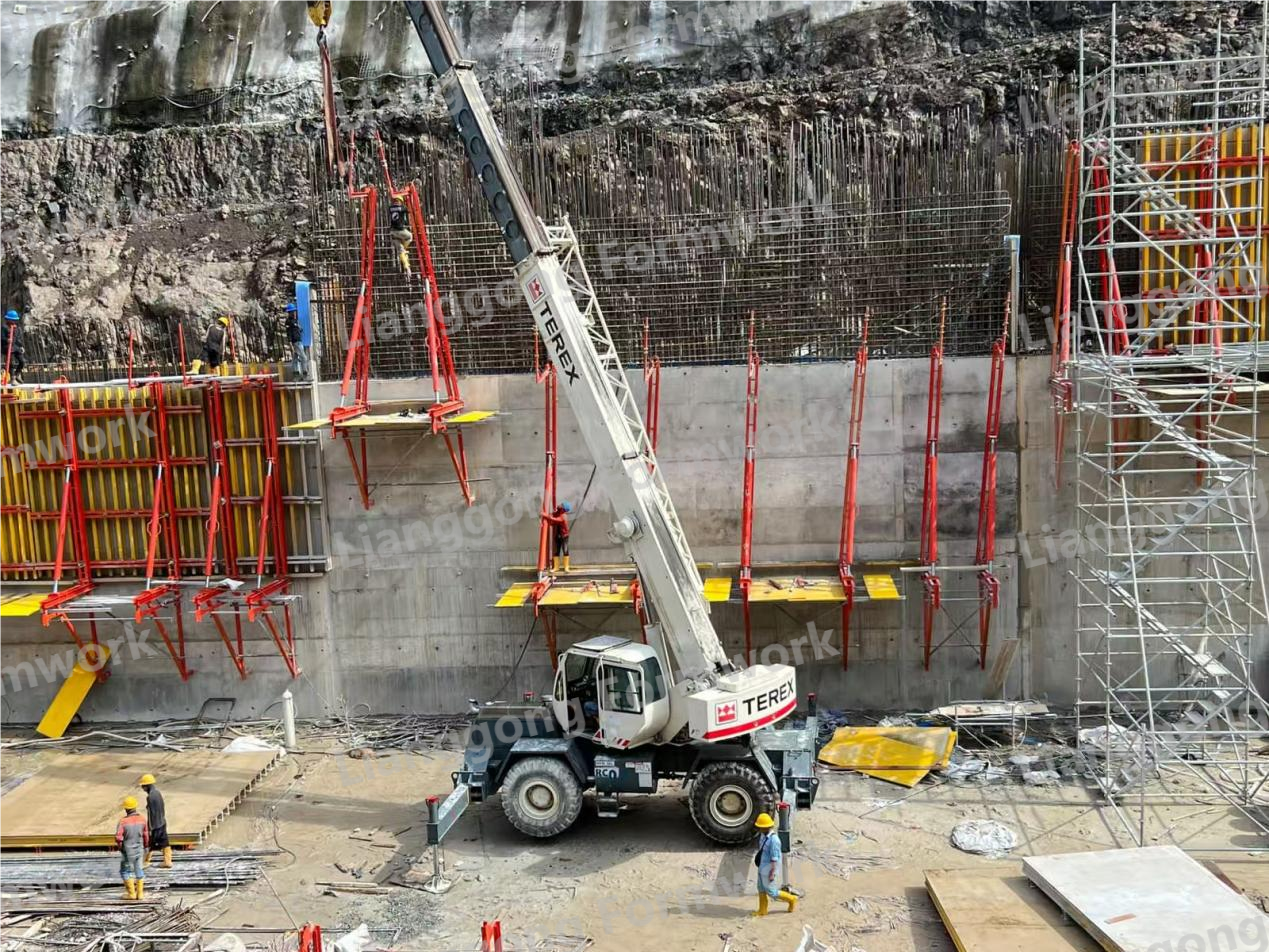

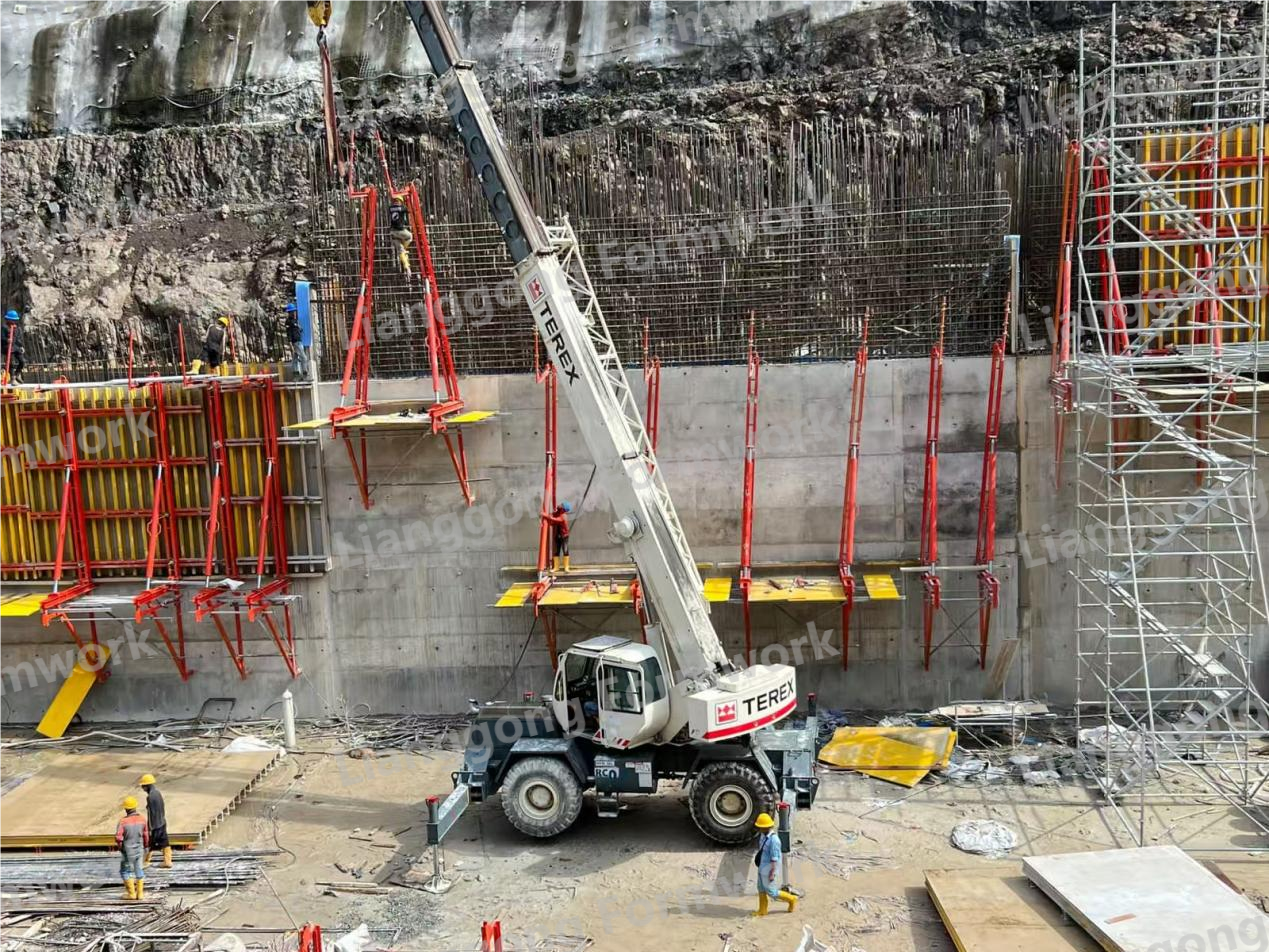

PT KERINCI MERANGIN HIDRO, an Indonesian hydropower leader, teamed up with Yancheng Liangong Formwork to build a reliable power plant. Our team supplied key tools like single - side formwork, H20 Timber beam systems, custom All-steel formwork, and cantilever systems. We didn't just meet the project's tough standards—we went above and beyond. By carefully checking every detail of our products, we made sure they could handle the heavy loads and constant water pressure of hydropower work.

2. Formwork Breakdow

This setup is like a space - saving hero. Perfect for tight spots, it holds up concrete walls without taking over the job site. Its easy - to - assemble design means workers can get the job done faster without sacrificing safety.

Think of it as the eco - friendly muscle of the project. Made from strong wooden beams, it's used for both vertical and horizontal construction and tough enough to support big concrete pours. Plus, it cuts down on waste, making it a win for both the budget and the planet.

When the project needed unique shapes, our steel formwork stepped in. We designed them specifically for PT KERINCI MERANGIN HIDRO, creating smooth curves and sharp edges that regular tools just can't handle.

This is the go - to for tall structures like dams. It clings to walls and moves up as the building grows, making it a time - saver for vertical projects.

3. Why We Stood Out

Service That Works for You:

We didn’t just drop off the products and leave. Our team was there from start to finish, helping with setup, answering questions, and fixing problems quickly. We believe good service means being there when you’re needed.

Results That Speak for Themselves:

The project’s success was evident in the seamless execution and long - lasting results. PT KERINCI MERANGIN HIDRO achieved their goals with minimal delays, and the final structures not only met safety standards but also exceeded expectations in terms of durability and finish.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

অসমীয়া

Беларуская мова

íslenska