Have you ever wished construction could be as easy as snapping Lego blocks together? Meet 65 Steel Frame Formwork—the ultimate "construction Lego" that turns complex column and wall projects into child’s play. As a 10-year leader in formwork innovation, Lianggong’s modular system blends simplicity, strength, and speed to save you time, money, and headaches.

A. Imagine a formwork system that:

✅ Adapts to Any Shape – Build columns from 200mm to 1050mm with just 9 standard panels

✅ Erects in Minutes – No heavy lifting or complicated tools required

✅ Lasts for Decades – Industrial-grade steel frame with replaceable plywood skins

B. Core Components:

· Panels: 12mm plywood riveted to Q235B steel frames (like a bulletproof sandwich)

· Accessories: Clamps, couplers, and wheels that work like magic to connect everything

2. Meet the Superhero Accessories

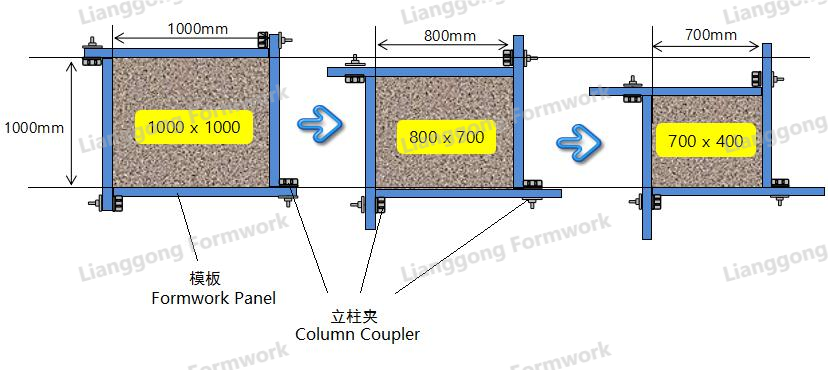

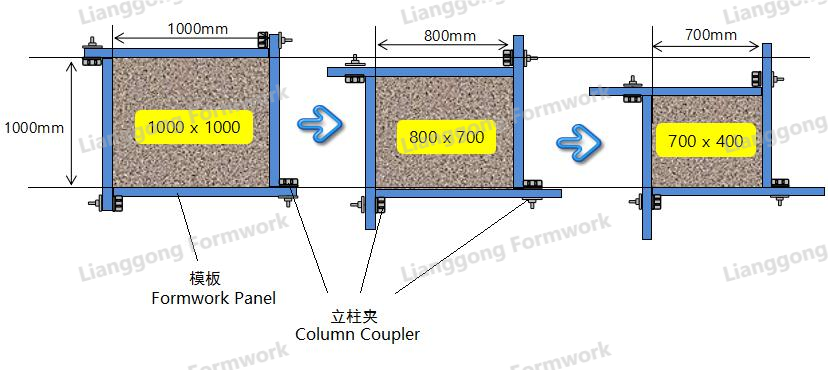

A. Column Couplers

· The "Swiss Army Knife" of formwork – adjust column sizes by sliding into 50mm spaced holes

· Example: Transform a 1000x1000mm column into an 800x700mm column in seconds

B. Standard Clamps

· Connect panels horizontally/vertically (like puzzle pieces)!

· Also doubles as ladder/work platform anchors – genius!

C. Casters with Handles

· Turn heavy panels into wheeled carts – move 3m panels with 1 person (no crane needed!)

3. How to Build Like a Pro

Step 1: Layout

Mark column positions on solid ground – think of it like drawing a treasure map.

Step 2: Assemble Halves

Connect panels with column couplers to create two U-shaped halves. It’s like building a giant letter "C".

Step 3: Stack & Secure

Use alignment clamps to stack panels vertically. Imagine building a skyscraper, but way faster.

Step 4: Add Extras

Attach work platforms (with standard clamps!), ladders, and lifting hooks. Safety first!

Step 5: Erect & Pour

Bring the two halves together, brace with push-pull props, and pour concrete. Done!

A. Cost Saver

· 50% faster installation than traditional methods

· Plywood replacement in 2 steps (rivet + seal) – cheaper than buying new panels

B. Superhero Strength

· 90kN/m² concrete pressure rating (can handle 9 elephants per square meter!)

· Galvanized steel options for coastal projects (rust-proof like a submarine)

C. Planet-Friendly

· 98% recyclable steel frame

· Reusable plywood skins save trees and landfill space

5. Real-World Wins

· Dubai Marina Tower: Built 50 columns in 3 days using 65 Steel Frame Formwork

· Sydney Metro: Reduced formwork costs by 35% with modular design

· Client Quote: "65 Steel Frame Formwork is like erector sets for adults – fun and functional!" – John Holland Group

6. Your 3 Reasons to Switch Today

· One-Size-Fits-All: 9 panels for 99% of column shapes

· 24/7 Support: Global team helps with CAD layouts and troubleshooting

· Future-Proof: Upgrade panels without replacing the entire system

7. Final Call

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe