1. A Deep Dive into Yancheng Lianggong's Steel Frame Formwork System

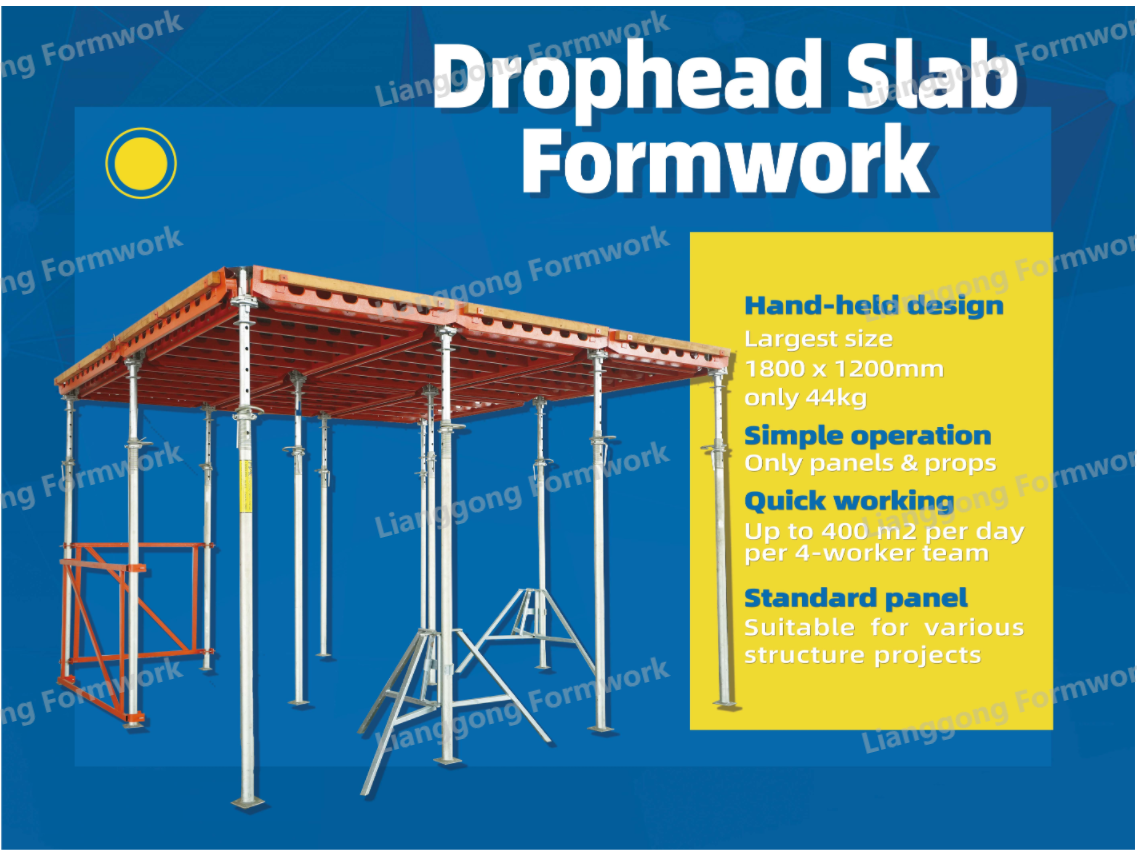

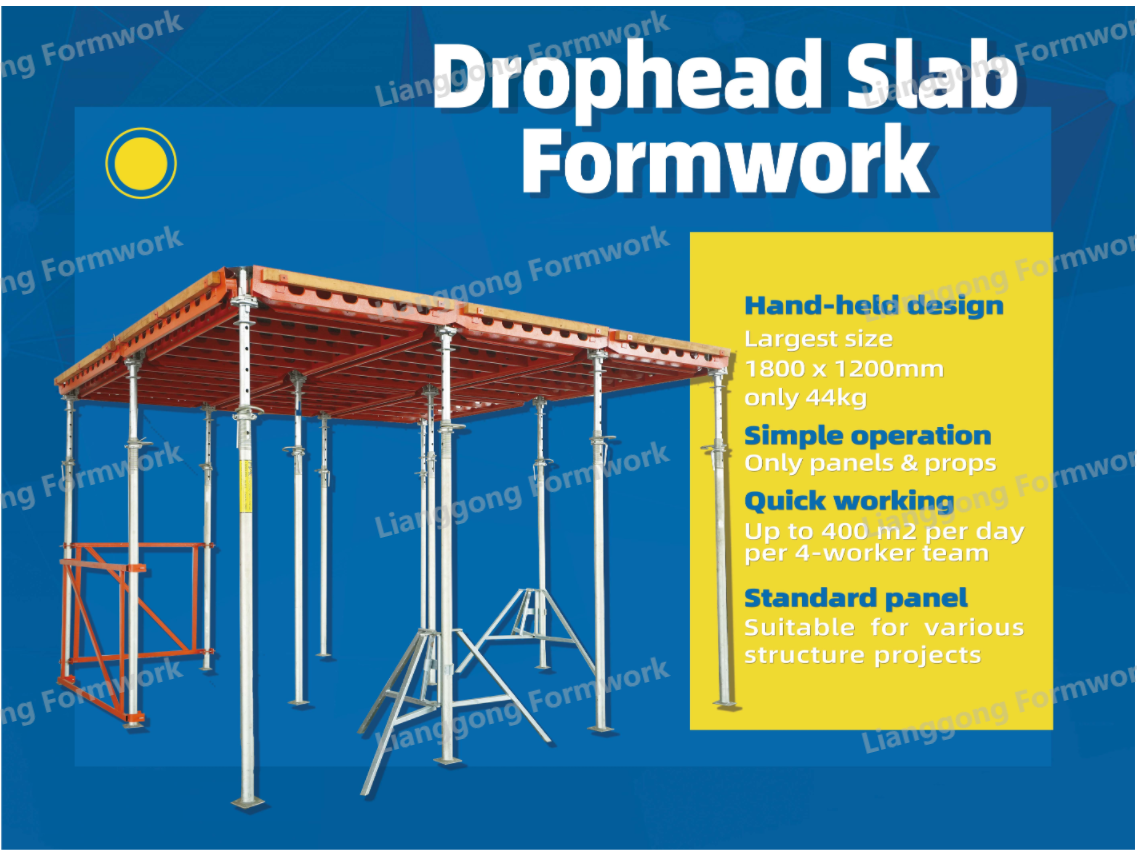

1.1 Horizontal Direction: Drophead Slab System

Yancheng Lianggong's horizontal setup is ideal for floor slabs. The formwork pairs a robust steel frame with quality plywood. The steel frame provides stability, while the plywood ensures a smooth finish.

For floors under 5 meters, they use steel props with early - release heads, speeding up formwork turnover. For taller floors, ring - lock scaffolding with an early - release device offers stability and efficiency.

1.2 Vertical Direction: Steel Frame Wall And Column Formwork

The vertical formwork panel features a 65 - mm - thick Q355B steel frame and 12 - mm - thick hardwood plywood with a PP plastic film. It's lightweight, durable, and waterproof. The plywood's 30 - plus reuses cut long - term costs. This formwork is perfect for walls and columns, ensuring solid vertical structures.

2. The Notable Advantages of Yancheng Lianggong's Steel Frame Formwork for Construction Sites

2.1 Reducing Construction Risks

Their modular steel frame setup cuts risks. The well - designed support structures, like early - release props and ring - lock scaffolding, are load - tested. The standard - fitted parts also make formwork removal safer.

2.2 Ensuring High - Quality Structures

From material selection to assembly, Yancheng Lianggong focuses on top - notch quality. The steel - plywood combo controls concrete shaping, ensuring accurate and stable structures. In wall and column construction, the formwork ensures smooth, strong pours.

2.3 Guaranteeing Column Verticality

2.4 Keeping the Construction Site Tidy

2.5 Facilitating Formwork Assembly and Reducing Defect Rates

2.6 Improving Demolition Safety with Universal Components

2.7 Material Utilization and Space Optimization

Yancheng Lianggong's setup uses materials efficiently, saving costs. On - site, its compact design maximizes working space, streamlining construction.

3. Conclusion

Yancheng Lianggong's modular steel frame setup excels in floor, wall, and column construction. It boosts safety, speeds up work, and improves quality. With material savings and site organization, it's a top choice for hassle - free, cost - effective construction projects.

Contact Us Now:

Global Hotline: +86 182 0105 1212

Business Email: sales01@lianggongform.com

Website: www.liangongform.com

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe