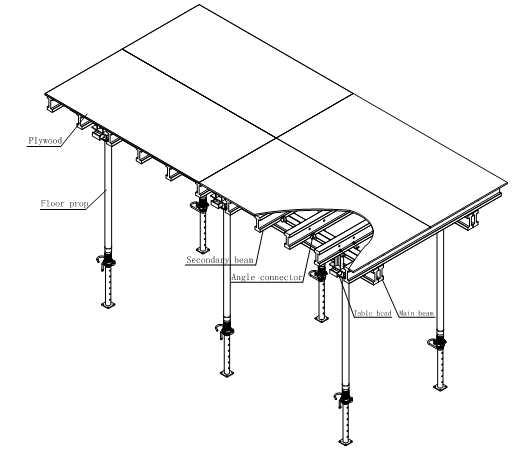

Table Formwork

Lianggong Table formwork is widely used for pouring floors in a variety of constructions, such as underground structures, multi-story factory buildings, and high-rise buildings. There is no need to disassemble the table formwork sets because they can be raised to the next level using a lifting fork once the concrete has been poured. Table formwork is easier to assemble, reuse, and has a simpler structure than traditional formwork. It has shortened construction timelines and decreased labor costs by eliminating the need for conventional slab support systems, which include cuplocks, steel pipes, and timber beams.

There are two typical sizes for Lianggong table formwork units: 2.44 x 4.88 m and 3.3 x 5 m.

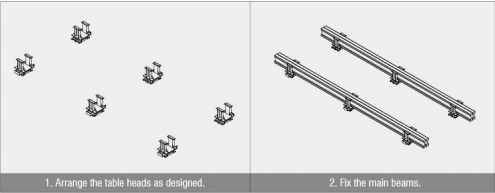

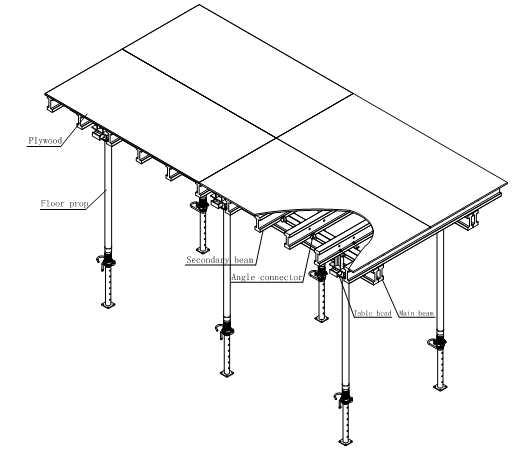

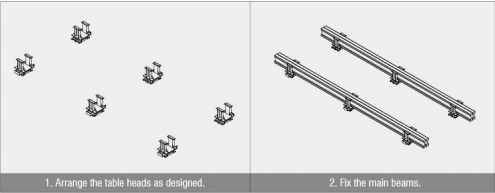

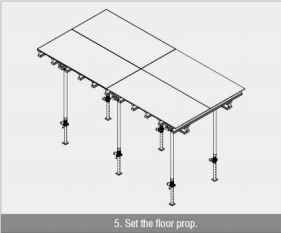

• Install the primary beams: Position the H20 timber beams atop the table heads and secure them in position utilizing suitable fasteners such as screws.

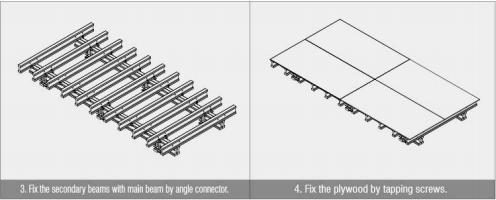

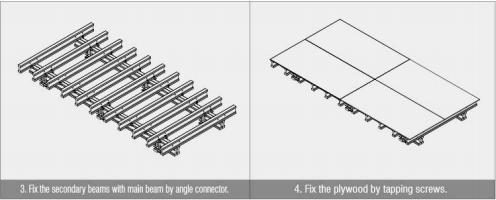

• Utilize angle connectors to join the secondary beams to the main beam: Establish connections between the secondary beams and the main beams at predetermined intervals.

• Utilize tapping screws to secure the plywood: Position the plywood panels atop the secondary beams and affix them in position with tapping screws.

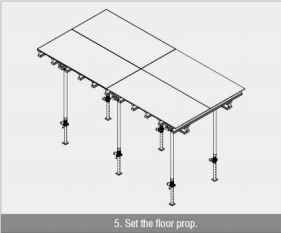

• Position the steel props: Adhere the steel props to the table heads and fasten them in position utilizing the corresponding fasteners.

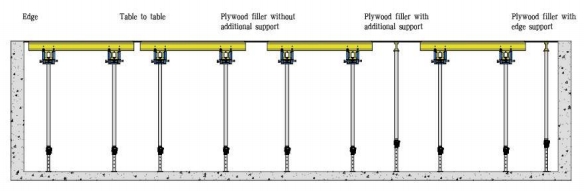

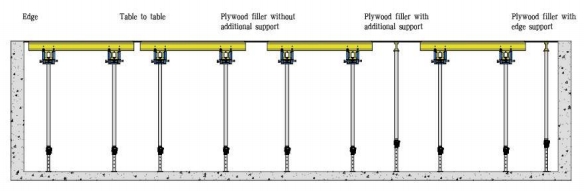

Plywood Filler and Steel Prop

In order to span a substantial distance between sets of conventional table formwork, plywood inserts may be applied. In order to secure the plywood infill to a steel support consisting of an H20 timber beam, table heads or four-way heads are unnecessary. Moreover, when an additional table formwork cannot be positioned at the floor's edge, support beams made of H20 timber and plywood must be utilized in conjunction with a steel anchor.

Characteristics

Numerous distinctive qualities of the table formwork system from Lianggong Formwork contribute to its widespread use in construction projects:

Flexibility: The modular design of the system facilitates rapid and effortless assembly and disassembly, thereby diminishing construction duration and labor expenditures.

Efficiency: The assembly process of the system is uncomplicated and can be effortlessly executed, resulting in a reduction of both construction time and labor expenses.

Even with frequent use, the system's H20 timber beams and plywood guarantee its durability and longevity.

Safety: The steel pillars, table heads, and tripods of the system reduce the likelihood of accidents and injuries on the construction site by providing stability and support for the beams and plywood.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe