Adjustable H20 Construction Table Formwork is a versatile and efficient solution for concrete slab casting. It includes steel beams, H20 wood beams and other connecting parts, which can be adjusted to different widths and heights according to project needs. The formwork is particularly suitable for complex floor slab layouts, especially in tight spaces.

The system supports large slab castings and provides reliable performance in various construction environments. The wooden flexible board formwork is supported by steel columns and tripods, with a plywood cover on top for concrete casting. It is designed for multi-story buildings, elevator shafts, staircases and villa projects, especially where crane capacity is limited.

Lightweight and easy to handle, the H20 wood beam formwork has high-quality bonding and rubber protection ends for added durability. Its simple structure allows easy assembly and disassembly, making it ideal for efficient construction. The system is fully reusable, reducing the overall cost of long-term use.

Adjustable H20 Tabletop Formwork is suitable for a variety of floor slab types and layouts. It ensures that construction projects run smoothly and efficiently, focusing on flexibility, speed and cost-effectiveness. Its transportability combined with standard packaging ensures easy use on different construction sites.

Product Parameters

| Parameter | Value |

| Certification | ISO |

| Material | Timber (H20 Timber Beam, Plywood) |

| Type | Table Formwork |

| Additional Support | Large panels require extra support |

| Horizontal Transport | Via transport trolleys |

| Vertical Transport | By crane with lifting forks |

| Weight | 43.86 kg/sqm |

| Panel Dimensions | 1220 x 2440 x 18mm plywood |

| Maximum Height | 5.0 m |

| Maximum Panel Thickness | 50 cm |

| Clear Height | 5.5 m |

| Transport Packaging | Standard packaging |

| Specifications | Customizable |

| Brand | Lianggong |

| Country of Origin | China |

| HS Code | 7308400000 |

| Production Capacity | 1500 sqm/month |

Features of Adjustable H20 Table Formwork For Constructiion

Durable Construction: The benchtop formwork is made of high-quality materials such as steel and wood, ensuring stability and durability throughout the construction process.

Modular System: The formwork is modular in design and can be easily customized to suit different project sizes and specifications. The versatility of the system makes it ideal for both small and large projects.

Quick Installation and Removal: The formwork panels are designed for quick installation and removal, reducing overall labor costs and time on site.

Reusable: The benchtop formwork is designed for multiple uses and can be reused in multiple construction phases, making it more cost-effective.

Strong Support: The system is capable of supporting heavy loads and is suitable for a variety of applications, including high-rise buildings and heavy civil infrastructure projects.

Safety: The benchtop formwork

Advantages of Adjustable H20 Table Formwork For Constructiion

Time Efficiency: The tabletop formwork can be quickly installed and removed, greatly speeding up construction time and ensuring efficient completion of projects.

Cost Savings: The system's reusability and quick installation and removal help reduce labor and material costs, making it an affordable choice for large projects.

Adaptability: The modular design makes the tabletop formwork highly adaptable to various types of construction, from residential buildings to large infrastructure projects.

High Load Capacity: The formwork system is designed to withstand the weight of concrete, ensuring stability even in heavy applications.

Safety and Stability: The tabletop formwork provides a stable and safe platform, reducing the risk of accidents on the construction site and ensuring that the work is completed safely.

Applications of Adjustable H20 Table Formwork For Constructiion

High-rise Buildings: The tabletop formwork is ideal for high-rise building projects, providing efficient and stable support for casting slabs.

Bridges: The system is often used in bridge construction to provide the necessary support for large-scale concrete pouring.

Commercial Buildings: Suitable for large commercial building projects, the tabletop formwork helps streamline the construction process.

Residential Buildings: This formwork is ideal for small and large residential projects, providing a reliable solution for casting concrete floors and slabs.

Infrastructure Projects: The system is widely used in various infrastructure projects such as tunnels, dams and other large civil engineering projects.

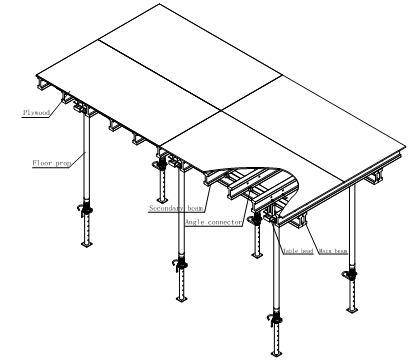

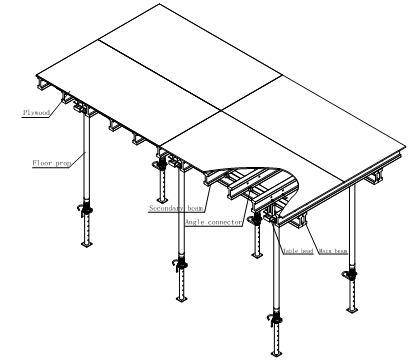

Standard unit of table formwork

Table formwork standard unit has two standard sizes: 2.44 × 4.88 m and 3.3 × 5 m. The structure diagram is as follows:

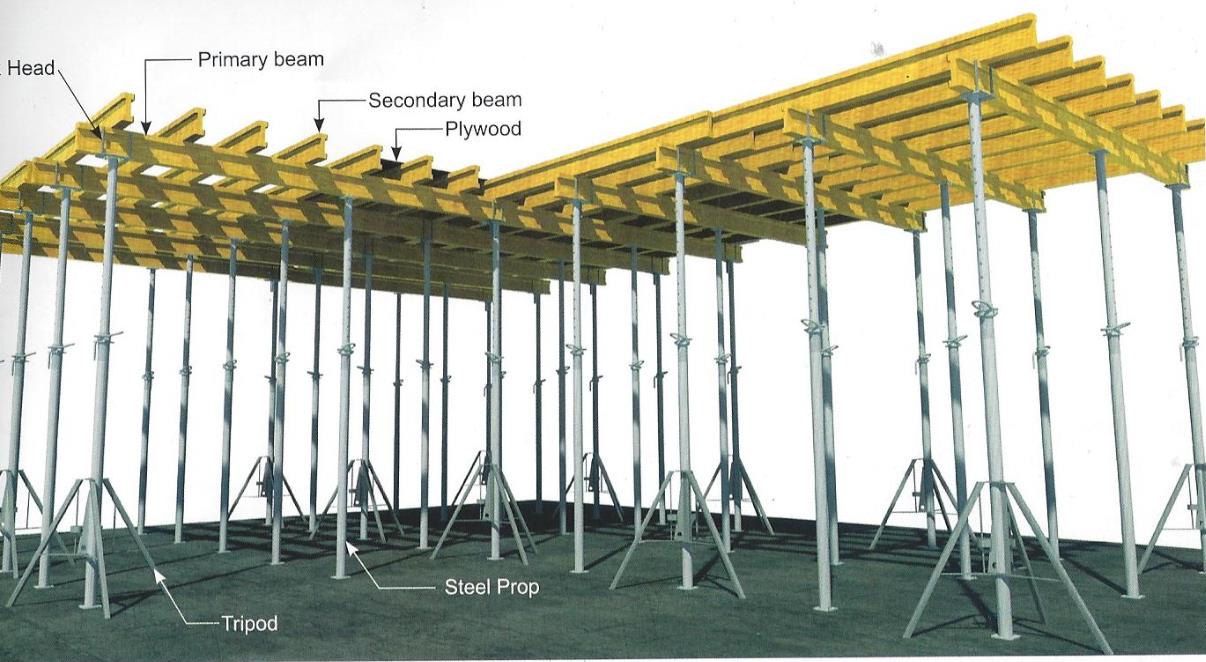

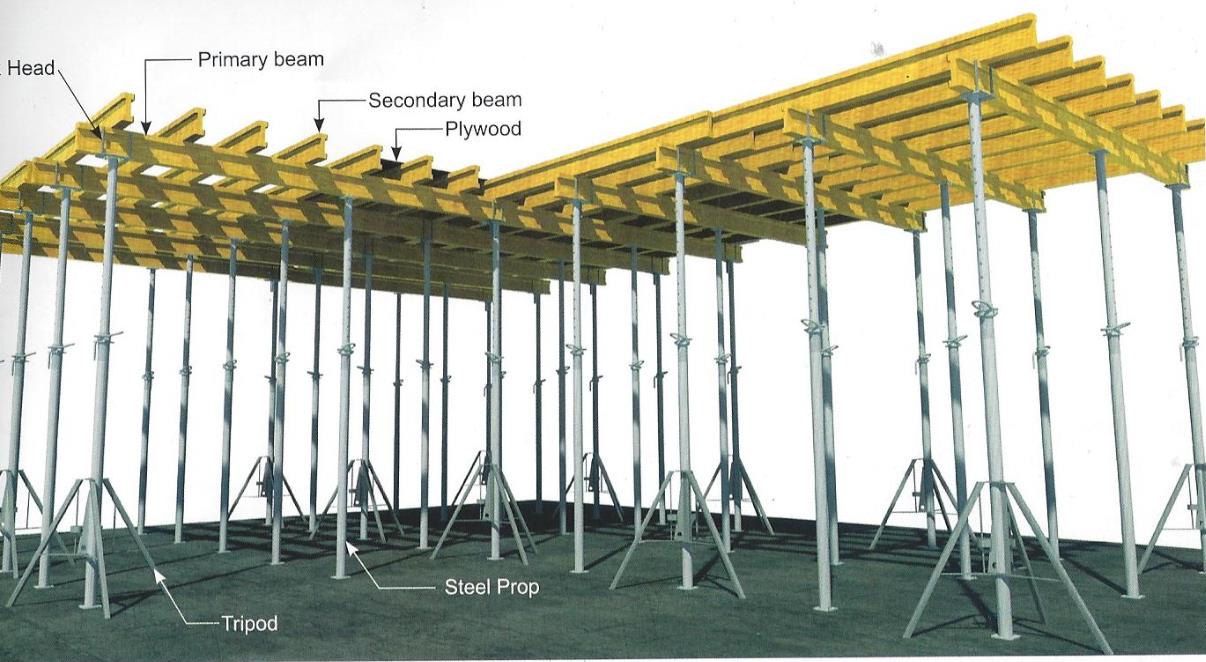

The flex-table formwork system

The flex-table formwork system, widely seen in the slab concrete pouring, is designed for complex floor plans especially in narrow space. It is supported by steel props and tripods with different support heads. H20 timber beams are adopted in this system as the primary and secondary beams, on top of which are plywoods as the panels. The system can be used for a clear height up to 5.90 m.

FAQs of Adjustable H20 Table Formwork For Constructiion

1. What is a Table Formwork?

Table Formwork is a modular concrete forming system used to cast large concrete slabs. It is easy to assemble and disassemble, and is an effective solution for high-quality concrete construction.

2. What are the main benefits of using Table Formwork?

The main benefits of using Table Formworkinclu de time efficiency, cost savings, adaptability to various project types, high load capacity, and increased safety for workers on site.

3. How long can a Table Formwork be reused?

The Table Formwork system is designed for multiple uses and long-term durability. It can be reused during the construction of multiple buildings or project phases.

4. Is the Table Formwork easy to install?

Yes, the Table Formwork system is designed for quick and easy installation. The panels are easy to assemble, reducing labor time and costs on site.

5. How does a Table Formwork improve safety on a construction site?

Table Formwork provides a stable and secure platform for workers, reducing the risk of accidents and ensuring safety at work.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe