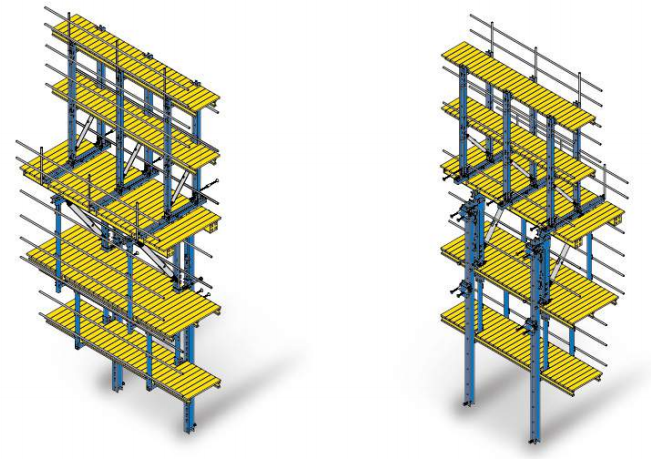

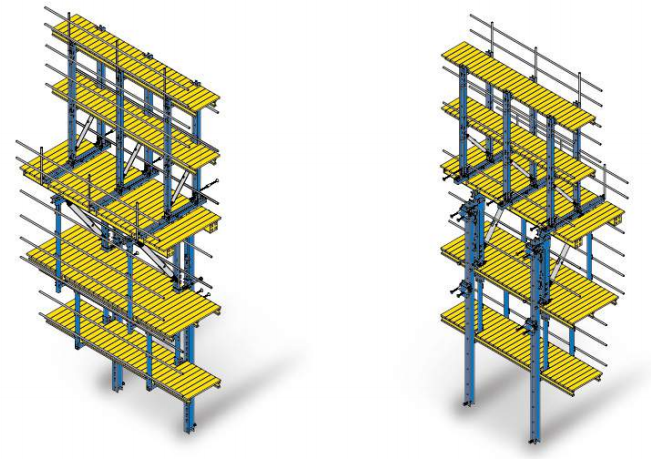

Hydraulic Auto-Climbing Formwork (ACS) is designed for high-rise building and bridge construction. It operates using its own hydraulic lifting system. The system includes hydraulic cylinders and diverters, which enable stable climbing without the need for a crane.

The Auto-Climbing Formwork Formwork is controlled by a hydraulic system that enables the main support and climbing rails to rise separately. This feature ensures that the Hydraulic Automatic Climbing System (ACS) is easy, fast and safe to operate. No additional lifting equipment is required, making it an ideal choice for construction projects.

The system is the first choice for high-rise tower and bridge construction due to its efficiency and reliability. The climbing speed is about 10 mm per second, which allows for efficient vertical ascent.

The Auto-Climbing Formwork system is customizable and is made of steel with a support height of 10-15 meters and a climbing height of 3-6 meters. It comes in standard packaging, and customized specifications are available to meet various project needs.

Product Parameters Table

| Parameter | Value |

| Model | Climbing Formwork |

| Material | Steel |

| Type | Auto-Climbing Formwork |

| Support Height | 10-15m |

| Climbing Height | 3-6m |

| Application | High-rise buildings, Shear walls, Bridge piers |

| Climb Speed | 10mm/second |

| Packaging | Standard packaging |

| Specification | Customizable |

| Brand | LIANGGONG |

| Origin | China |

| Production Capacity | 200 sets per month |

| Minimum Order Quantity | 1 Set |

| Customization | Available |

| After-sales Service | Provided |

| Warranty | 1 year |

Features of Hydraulic Auto-Climbing Formwork

Independent hydraulic Auto-Climbing Formwork: suitable for high-rise building and bridge construction, providing reliable vertical climbing.

Power source: It is operated by a hydraulic system including pumps, hydraulic cylinders and oil pipes, without the need for a crane.

Fast climbing: The system can easily climb vertically or inclined to increase construction speed.

Stable synchronous climbing: The Auto-Climbing Formwork climbs as a whole or in part to ensure stability, synchronization and safety.

Minimize the risk of damage: The Auto-Climbing Formwork remains intact until the construction is completed, reducing on-site space requirements and minimizing the risk of damage.

Complete operating platform: Provides an integrated operating platform, without the need for an additional platform, reducing material and labor costs.

Reduce construction errors: Simple calibration can correct errors layer by layer to ensure the accuracy of construction.

Fast climbing speed: The system climbs quickly, speeding up the construction progress (average per layer: 5 days).

Advantages of Hydraulic Auto-Climbing Formwork

Easy Construction: Seamless construction with minimal manpower, ideal for large projects.

Customization Options: Customizable lengths and colors (blue or other customized options) are available to meet project needs.

High Pressure Resistant: Able to withstand up to 80KN of fresh concrete pressure, ensuring stability in demanding environments.

Comprehensive After-Sales Service: Including online technical support, on-site installation, training and inspection services.

Wide Application: Suitable for a variety of uses, including high-rise buildings, dams, bridge piers and cable towers.

Complete Platform System: Provides a complete platform, no additional platform required.

Applications of Hydraulic Auto-Climbing Formwork

High-rise buildings: suitable for high-rise building construction that requires vertical rise.

Dam: suitable for large dam construction, providing stability and efficiency.

Bridge pier: used to build strong and durable bridge piers.

Cable tower: suitable for the construction of high-voltage transmission cable towers.

Our Service

Consultation, Design and Quotation: Provide project-specific system concepts, design based on structural drawings, and provide customized quotations.

Manufacturing and Quality Inspection: Large-scale production facilities with advanced production lines and a professional quality inspection team ensure high standards of products.

Packaging and Transportation: Standard export packaging is used from manufacturing to loading to ensure fast delivery to the site.

Remote or on-site guidance: Provide remote or on-site support for any issues to ensure peace of mind and satisfaction throughout the process.

FAQs

1. What is the use of hydraulic Auto-Climbing Formwork?

Designed for high-rise building and bridge construction, the system provides stable vertical ascent during construction.

2. What are the advantages of formwork climbing speed?

The Auto-Climbing Formwork can climb quickly, and the construction of each floor can be completed in about 5 days, which greatly speeds up the construction progress.

3. Can the Auto-Climbing Formwork climb in different directions?

Yes, the system can climb vertically and inclined, providing flexibility for various construction designs.

4. How does the system ensure safety and stability during climbing?

The formwork climbs steadily and synchronously as a whole or in blocks to ensure safety.

5. Does the formwork remain on site after construction?

Yes, the formwork is not removed until the construction is completed, minimizing the risk of damage and reducing space requirements.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

অসমীয়া

Беларуская мова

íslenska