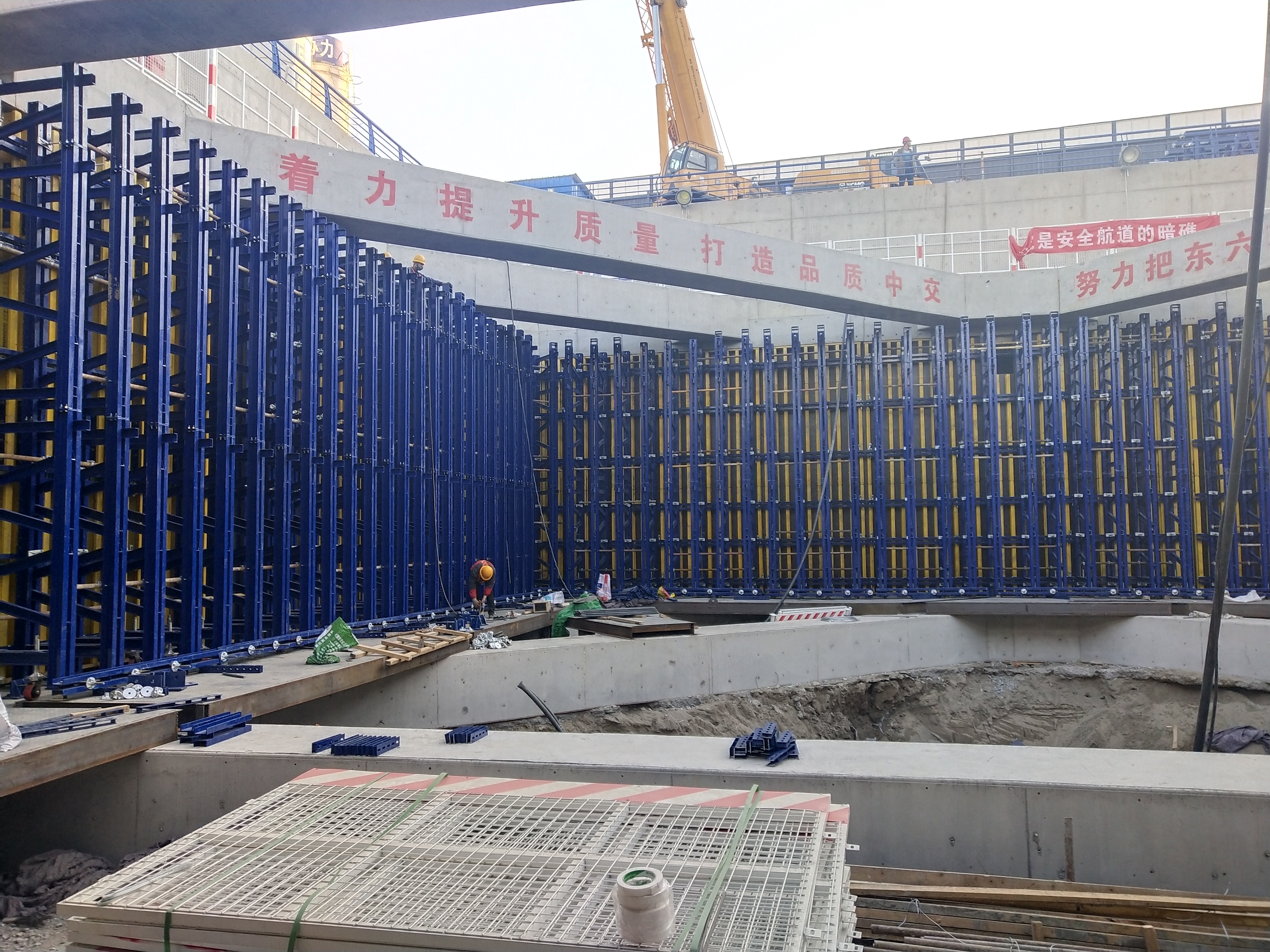

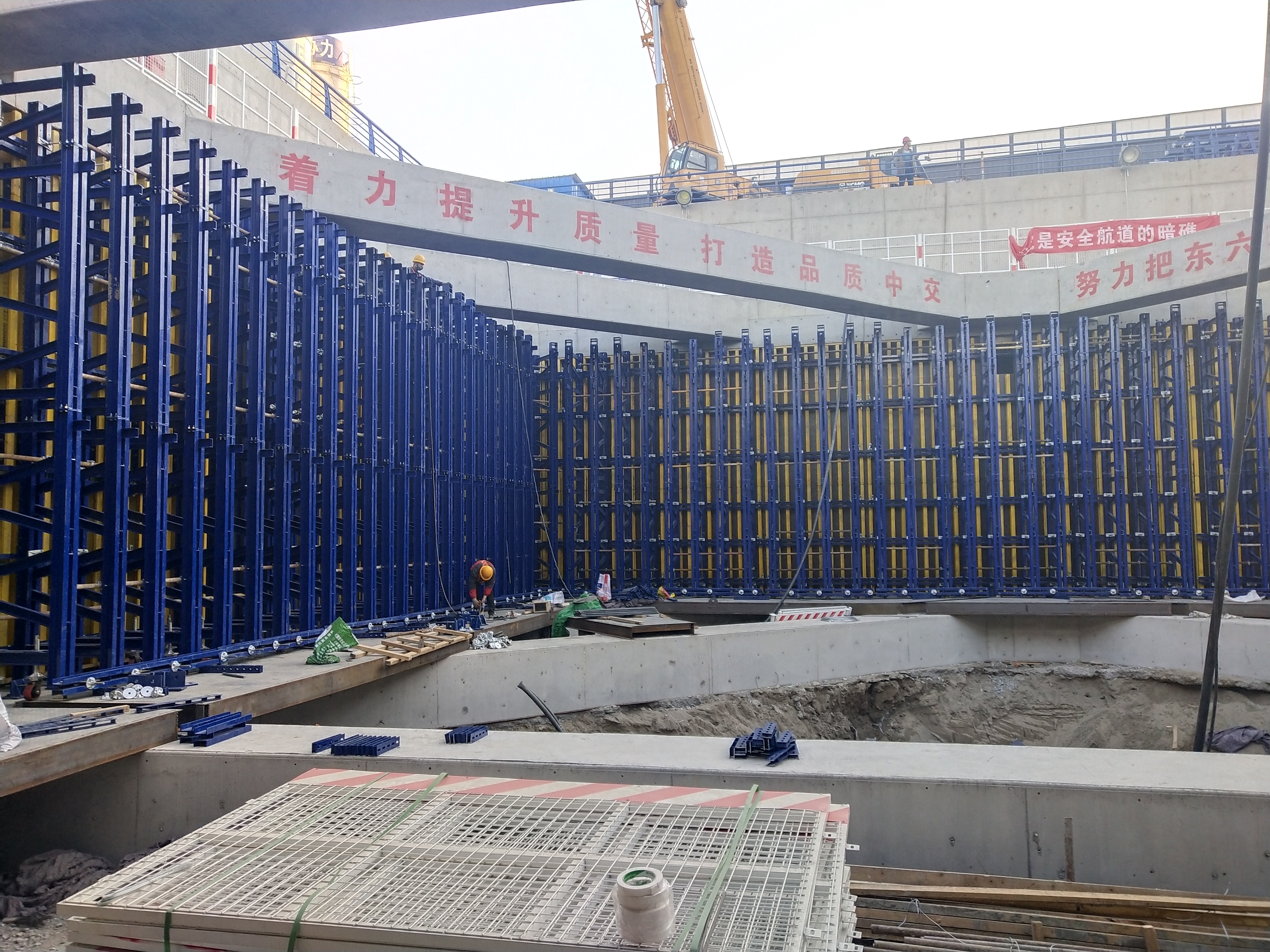

The concrete retaining wall steel single-sided bracket is designed for single-sided concrete pouring. It provides an effective solution for formwork and is widely used in basements, sewage treatment plants, subways and bridge slope protection. The bracket system is simple to install and its design does not require through-wall tie rods, ensuring that the wall is waterproof after pouring.

This bracket is particularly effective in spaces where traditional methods are impractical. It controls the lateral pressure of concrete during pouring, thereby simplifying the process and improving safety. With a maximum pouring height of 7.5 meters in one pour, the system ensures efficient and stable concrete pouring.

The size and color of the steel single-sided bracket can be customized to meet specific project requirements. It includes brackets, formwork and anchoring components to provide a comprehensive solution for construction projects. This system is a reliable choice for projects that require fast installation, heavy-load support and long-lasting performance.

Product Specifications

| Parameter | Value |

| Material | Steel |

| Type | Single-Side Wall Formwork |

| Color | Yellow, Blue, or Customized |

| Reusability | 50-80 cycles |

| Panel Thickness | 6 mm |

| Width | 1,000-3,000 mm |

| Maximum Lateral Pressure | 80 kN/m² |

| Height | 3,000-6,000 mm |

| Railing Height | 1,200 mm |

| Application Scope | Subways, Basements |

| Platforms per Level | 3 m per level |

| Platform Width | 900 mm |

| Transport Packaging | Boxes, Steel Pallets, Steel Frames, Containers |

| Origin | China |

Features of Steel Single-Side Bracket For Concrete Protecting Wall

High load-bearing capacity: Designed to withstand large lateral concrete pressure, ensuring structural integrity during casting.

Adjustable size: Customizable sizes are available to meet different project requirements.

Durable structure: Made of high-quality steel, durable and wear-resistant.

Easy to assemble: Designed for quick installation and removal, reducing labor time and costs.

Safety features: Combined with safety platforms and railings to improve worker safety during operation.

Advantages of Steel Single-Side Bracket For Concrete Protecting Wall

Waterproof structure: No through-wall tie rods are required, and the wall is completely waterproof after casting.

Beam formwork

Versatility: Suitable for a wide range of construction applications, from underground structures to large public buildings.

Economical and efficient: Reusable design allows multiple uses, optimizing investment over time.

Reinforced structural support: Provides reliable reinforcement for single-sided walls, maintaining formwork stability without deformation.

Applications of Steel Single-Side Bracket For Concrete Protecting Wall

Basements: Suitable for building waterproof exterior walls in underground environments.

Wastewater treatment plants: Suitable for forming durable, impermeable walls in sewage treatment facilities.

Metro: Suitable for the development of underground transportation systems, ensuring a strong wall structure.

Road and Bridge Slope Protection: Used in infrastructure projects to support and protect inclined surfaces.

FAQs of Steel Single-Side Bracket For Concrete Protecting Wall

1. What is the main function of the steel single-sided bracket?

It is designed for single-sided concrete wall applications, providing support during the casting process without the need for through-wall tie rods.

2. What is the maximum lateral pressure that the bracket can withstand?

It can withstand a maximum lateral pressure of 80 kN/m², ensuring stability during concrete pouring.

3. How many times can the bracket be reused?

The bracket is designed for a reuse rate of 50-80 times, depending on maintenance and usage conditions.

4. What safety features are included in the design?

The system includes 1,200 mm high railings and 900 mm wide operating platforms to improve worker safety during operation.

5. How is the bracket packaged for transportation?

Packaging options include boxes, steel pallets, steel racks and containers to ensure safe and efficient transportation.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

অসমীয়া

Беларуская мова

íslenska