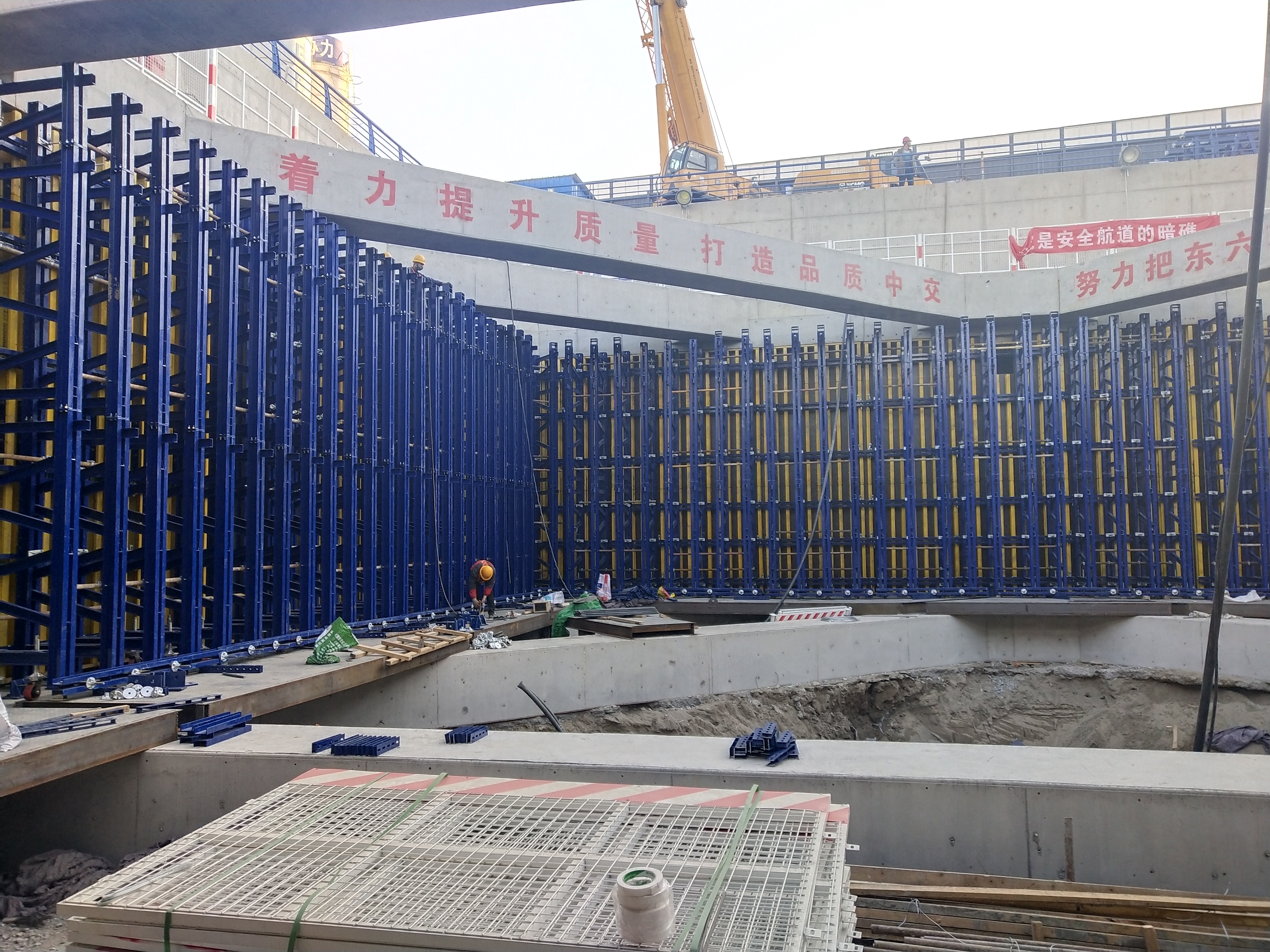

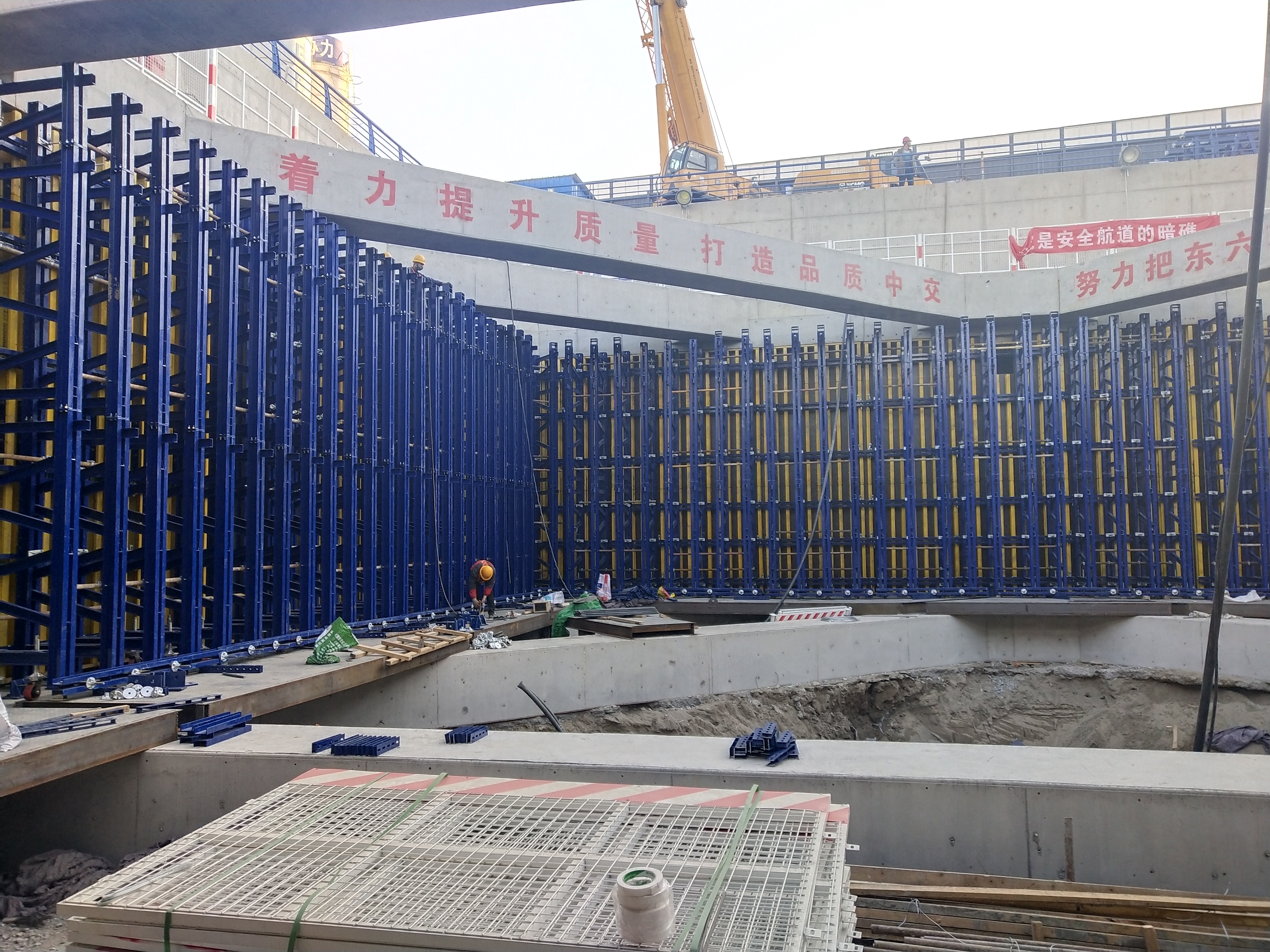

Lianggong Steel Single Side Bracket Wall Formwork is designed for efficient and stable vertical concrete construction. It consists of high-quality components such as H20 wooden beams, steel cross braces and film-faced plywood. This formwork system is pre-assembled and can support concrete pressures from 50 to 90 KN/m², suitable for demanding construction projects.

The system's customizable design and sturdy materials ensure adaptability and durability. Using pre-assembled components, it reduces on-site labor and assembly time, providing a cost-effective and reliable solution for retaining walls, basement walls and other vertical structures.

Product Parameters Table

| Parameter | Value |

| Model | 18000000 |

| Type | Formwork |

| Material | Film Faced Plywood 1220×2440×18mm |

| Components | H20 Timber Beam, Steel Waler, Plywood |

| Pre-Assembled | Yes |

| Concrete Pressure | 50–90 KN/m² |

| Trademark | ForPro |

| Specification | Customized |

| Plywood Thickness | 18mm & 21mm, max size 2m×6m (customized) |

| Timber Beam Size | Height: 200mm, Width: 80mm, Length: 1m–6m |

| Steel Beam | Welded Double U-Shape (100 or 120) with slot holes for universal application |

Features of Steel Single-Side Bracket Wall Formwork For Concrete Construction

Application: Provides reliable trench support during excavation as a form of ground stabilization.

System size: Determined by the maximum trench depth and the size of the pipe installed for optimal safety.

Depth suitability: Designed for trenches up to 4 meters deep and 3.7 meters wide.

Preassembled system: Delivered preassembled for quick and easy installation on site.

Panel size: Standard panels measure 3.00m x 2.00m and are connected with adjustable spacers.

Extension excavation: Extension elements can be included by combining panels to achieve a maximum depth of 4.40 meters.

Advantages of Steel Single-Side Bracket Wall Formwork For Concrete Construction

Lightweight design: Made of a combination of wood and steel, it is lighter than all-steel formwork.

Easy to modify: The components are highly adaptable and environmentally friendly, reducing waste.

Smooth concrete finish: Fewer holes on the plywood surface, better concrete quality.

Safe and durable: Designed for long-term use, safe and reliable when pouring concrete.

Customizable solutions: Other formwork systems can be adapted according to ForPro's custom design.

Standardized performance: Provide consistent quality and flexibility for a variety of projects.

Quick assembly: Components connect quickly to ensure fast on-site setting.

Waterproof effect: Ensures waterproof walls with excellent finishing quality.

Optimized transportation: Compact design, efficient transportation and storage.

Applications of Steel Single-Side Bracket Wall Formwork For Concrete Construction

LNG storage tanks: Ideal for the walls of liquefied natural gas storage facilities.

Dam: Provides reliable support for concrete structures in dam construction.

High-rise buildings: Suitable for retaining walls in high-rise building projects.

Bridge towers: Concrete towers used to form bridges and overpasses.

Nuclear power projects: Suitable for building vertical structures in nuclear power facilities.

FAQs of Steel Single-Side Bracket Wall Formwork For Concrete Construction

1. What is the purpose of the Steel Single Sided Support Wall Formwork?

It is used for vertical concrete structures that require single-sided support, such as retaining walls and basement walls.

2. What material is used for the formwork?

The system is made of high-strength steel for durability and stability.

3. Can this formwork be reused?

Yes, the formwork is designed for multiple uses and is a cost-effective solution.

4. Is the formwork easy to assemble?

The modular design ensures fast and efficient on-site assembly and disassembly.

5. What types of projects is this formwork suitable for?

It is ideal for retaining walls, basement walls, abutments and industrial structures.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe