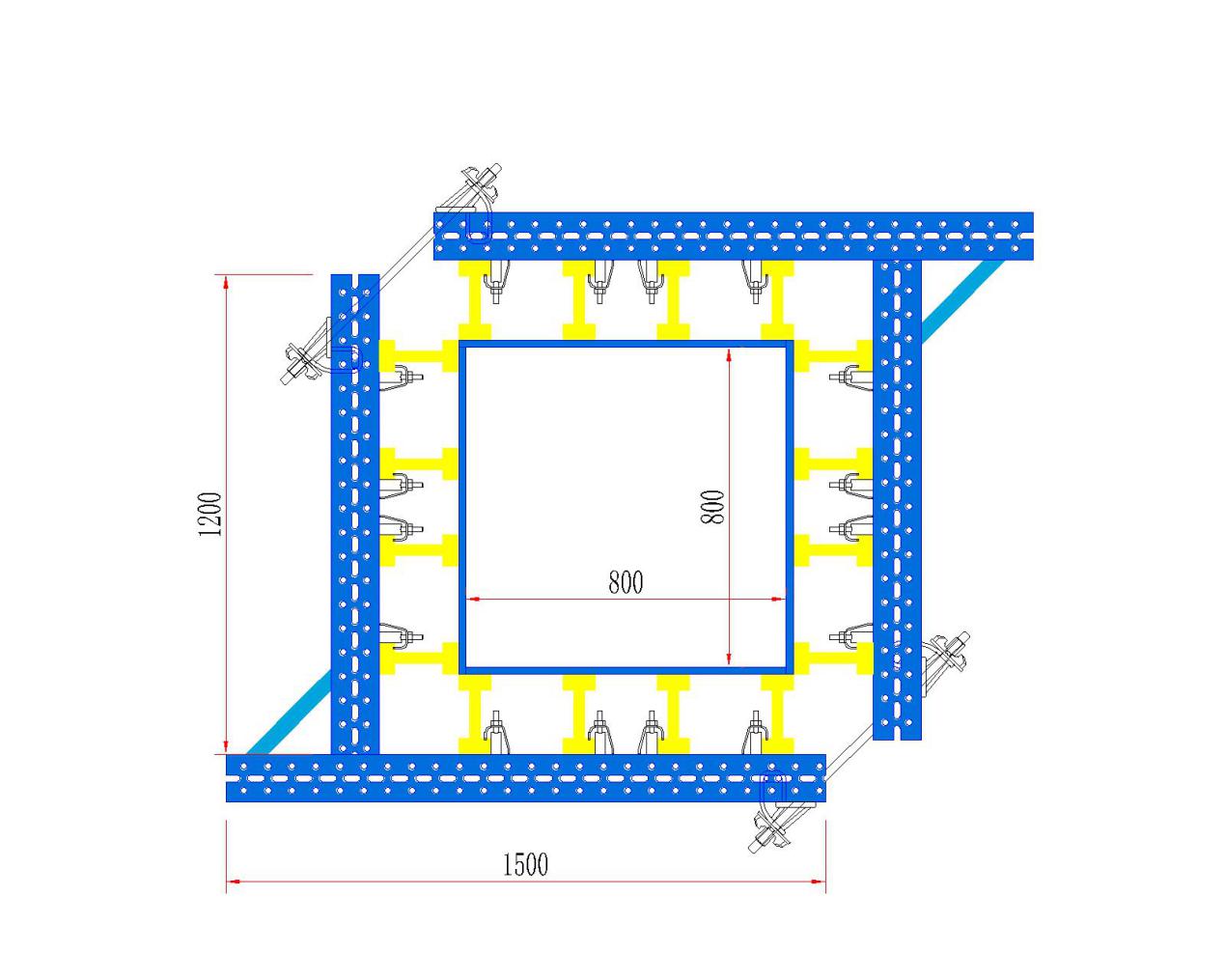

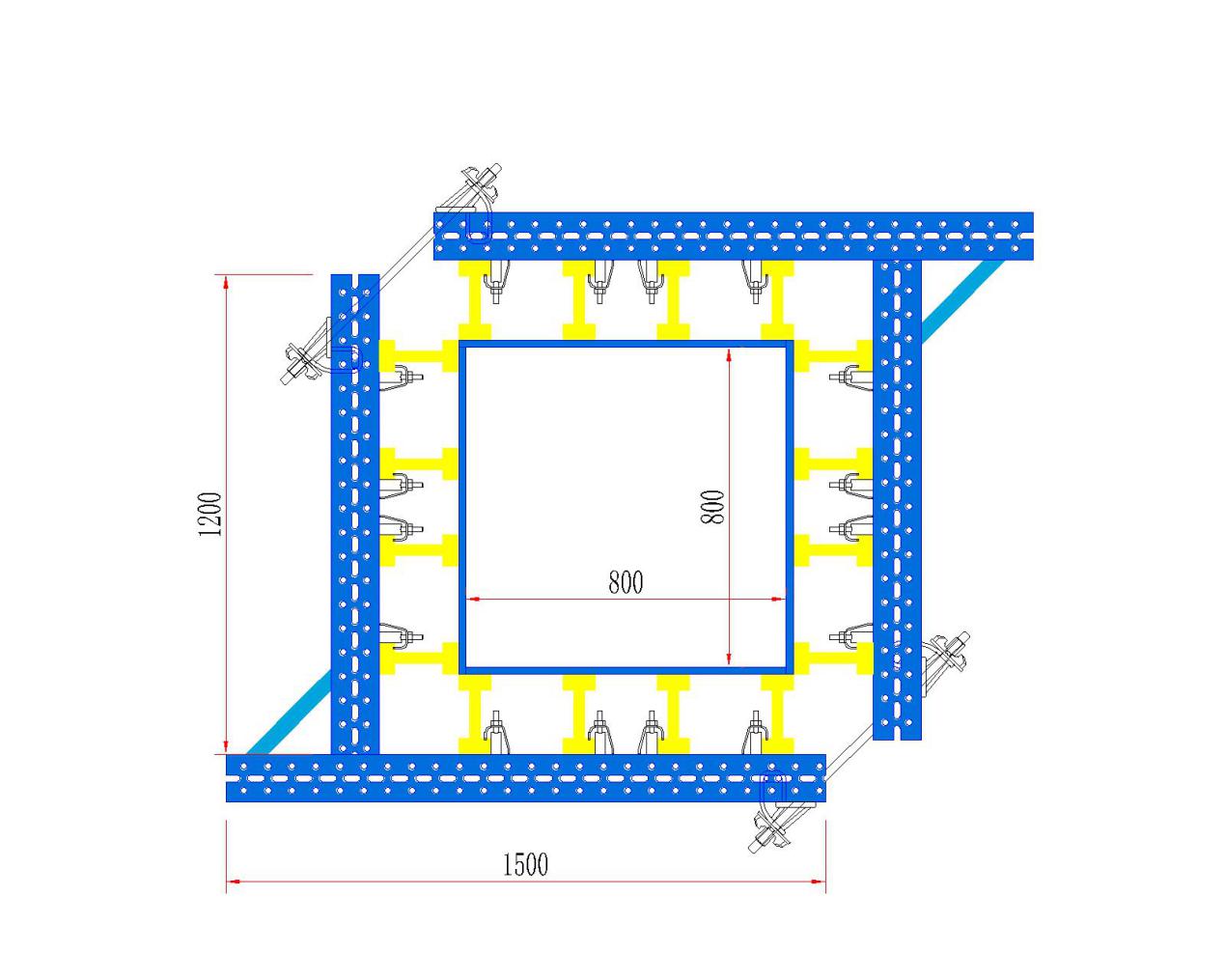

This timber column formwork system is designed to provide an efficient and reliable solution for concrete column casting in various construction projects. Its customizable size and high load capacity allow it to adapt to different structural requirements. The use of high-quality wooden beams, plywood, and steel struts ensures durability and stability during the casting process. In addition, auxiliary equipment such as lifting forks and mobile trolleys are included to facilitate on-site handling and repositioning. This formwork system is certified by ISO, ROHS, and CE, etc., complying with international quality and safety standards. Its yellow color improves visibility on the construction site and helps create a safer working environment. Overall, Lianggong's H20 wooden column formwork provides a versatile and reliable solution for modern construction needs.

Product Specifications

| Parameter | Value |

| Model | H20 Timber Column Formwork |

| Certification | ISO, ROHS, CE |

| Materials | Timber Beam, Plywood & Steel Props |

| Type | Slab Formwork |

| Load Capacity | 5~15 kN/m² |

| Color | Yellow |

| Auxiliary Equipment | Lifting Fork, Shifting Trolley |

| Customizable Size | Yes |

| Transport Packaging | Steel Pallet or Customized |

| Specifications | Customized as per requirements |

| Production Capacity | 20,000 pieces/year |

| Description | Widely used in bridges, nuclear power plants, hydropower stations, and large public buildings; easy to process and modify. |

Features of H20 Timber Column Formwork For Casting Columns

Weight: Approximately 4.5 kg per meter, making it easy to handle and install on the construction site.

GF TECH

Core Material: Made of poplar plywood, it provides a balance between strength and flexibility for a variety of formwork applications.

Packaging: Supplied in 105 pieces per pallet, optimizing storage and transportation efficiency.

Moisture Content: Delivered with a moisture content of 12% ± 4%, ensuring dimensional stability and reducing the risk of warping.

Shear Resistance: Able to withstand shear forces up to 11 kN, ensuring structural integrity during concrete pouring.

Bending Resistance: Supports bending forces up to 5 kN, maintaining the formwork shape under load.

Flange Material: Made of imported Nordic spruce, known for its durability and resistance to environmental factors.

Available Lengths: Available in standard lengths from 1.5 meters to 5.9 meters, with custom lengths available to meet specific project requirements.

Advantages of H20 Timber Column Formwork For Casting Columns

Yellow Waterproof Coating: The H20 timber column formworks are treated with a yellow waterproof coating, which enhances their moisture resistance and extends their service life in various construction environments.

FUSHI WOOD GROUP

Customizable lengths up to 6 meters: These beams can be customized to specific project requirements in lengths up to 6 meters, with great flexibility to meet a variety of construction needs.

Plastic End Caps: Both ends are equipped with plastic caps to protect the beams from mechanical damage during handling and installation, thereby extending their service life.

Nordic Spruce Structure: Made of high-quality Nordic Spruce, known for its excellent load-bearing capacity and durability, ensuring reliable performance in demanding construction applications.

Applications of H20 Timber Column Formwork For Casting Columns

Bridges: Ideal for constructing formwork in bridge projects, providing the necessary support for casting concrete components.

Nuclear Power Plants: Suitable for the stringent requirements of nuclear facility construction, ensuring the precision and safety of formwork application.

Hydropower Plants: Suitable for hydropower infrastructure construction, helping to form complex concrete structures.

Large Public Buildings: Suitable for large public building projects, helping to efficiently cast columns and other structural components.

FAQs of H20 Timber Column Formwork For Casting Columns

1. What is the maximum permissible pressure for this Timber Column Formwork?

It can withstand concrete pressures of up to 80 kN/m².

2. Can the formwork be adjusted to accommodate different column sizes?

Yes, it offers flexible adjustment to accommodate a wide range of column sizes.

3. What are the available lengths of the H20 Timber Column Formwork?

Standard lengths range up to 6 meters, with custom lengths available on request.

4. Can the formwork be reused?

Yes, it is designed for multiple uses, as long as it is properly maintained.

5. How is the formwork protected against moisture?

The beams are treated with a yellow waterproof coating to enhance moisture resistance.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe