Speed in slab construction is rarely decided by pouring alone. On many projects, delays come from repeated handling of materials, constant re-measuring, and inefficient stripping rather than from concrete placement itself. Every extra adjustment, every misplaced prop, and every unnecessary lift adds minutes that accumulate into lost days. This is why many contractors re-evaluate their slab systems when schedules become tight. For projects using H20 Timber Beam Formwork, the comparison between flex-slab formwork and traditional slab formwork often comes down to one central question: which system truly delivers faster floor cycles under real site conditions? This article breaks slab construction into clear stages and explains how flex-slab formwork typically accelerates each step, while also showing when its speed advantage matters most.

What Flex-Slab Formwork Is in Plain Terms

Flex-slab formwork is designed around the idea of modular repetition rather than on-site improvisation. Instead of cutting timber to fit every new slab bay, the system relies on standardized components that can be rearranged quickly.

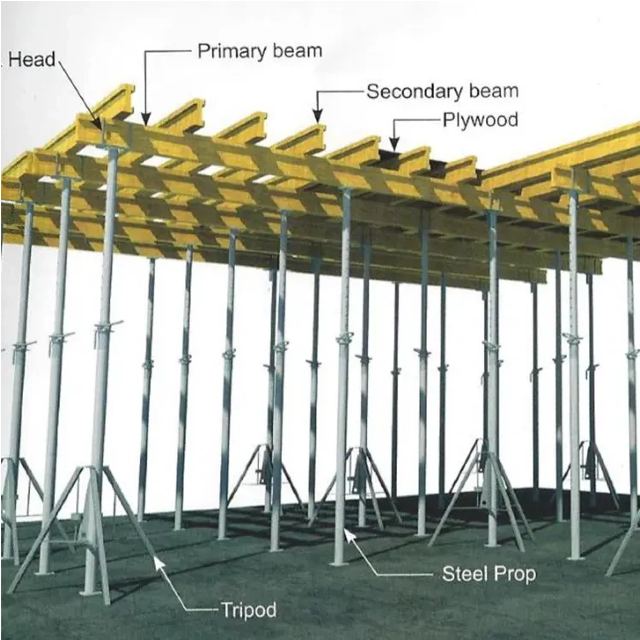

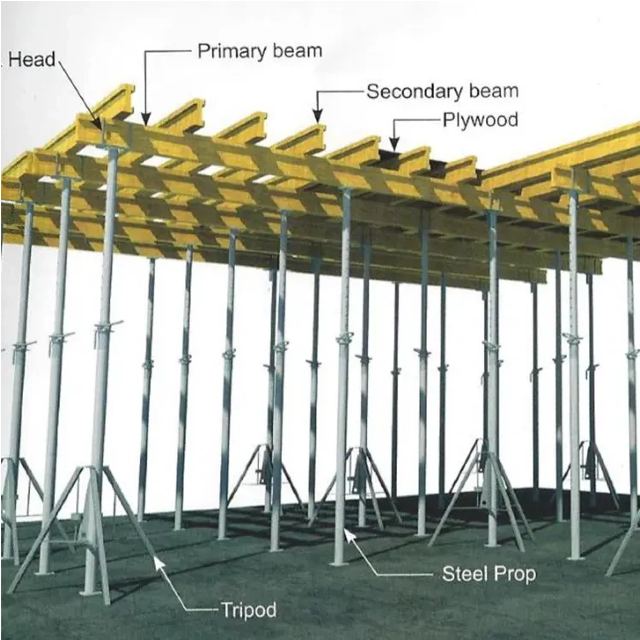

Modular Primary and Secondary Beams With Props and Tripods

At the core of a flex-slab system are primary and secondary H20 timber beams arranged in a regular grid. These beams are supported by adjustable steel props and stabilized during setup with tripods and connectors. Because the beam lengths and spacing follow a modular logic, crews spend less time deciding where each element belongs. The structure of the system itself guides assembly, reducing the need for constant measurement and correction.

Height Adjustability and Why It Speeds Leveling

One of the most time-consuming tasks in slab formwork is leveling. Traditional systems often require repeated adjustments as props settle or loads change. Flex-slab formwork uses adjustable heads and props that allow fine height control at each support point. This makes it easier to reach the required slab elevation quickly and maintain it throughout the pour. Fewer leveling iterations translate directly into faster preparation time.

How Durability Secures Slab Cycle Continuity

Durability also affects speed. When components are designed to withstand repeated handling and exposure, downtime caused by repairs or replacements is reduced. Flex-slab systems use robust timber beams and steel components that maintain performance over many cycles. This durability minimizes interruptions and keeps the slab cycle predictable.

Where Time Is Usually Lost in Traditional Slab Formwork

To understand why flex-slab formwork is often faster, it helps to identify where traditional slab formwork typically loses time.

Re-Cutting and Re-Measuring

Traditional slab formwork often relies on cut-to-fit timber and individually placed props. Each new bay or layout change requires fresh measurements and cutting. Even small inaccuracies can force crews to redo work, slowing progress. This repeated measuring and cutting consumes significant labor hours, especially on projects with complex geometry.

Too Many Small Parts Lead to Slower Stripping

Another major time sink appears during stripping. Traditional systems use many small, independent elements that must be removed one by one. This process is not only slow but also increases the risk of damage or misplacement. The lack of a clear disassembly sequence often leads to congestion and inefficiency during stripping.

Quality Fixes After Pouring

Uneven soffits and misaligned supports are common issues with traditional formwork. Fixing these problems after the pour takes additional time and labor. When slab surfaces require grinding or patching, the schedule impact extends beyond the formwork cycle itself.

Speed Breakdown: Which Steps Flex-Slab Accelerates

Flex-slab formwork addresses these time losses by streamlining each stage of the slab construction process.

Setup With Standardized Spacing and Repeatable Placement

During setup, flex-slab systems rely on predefined beam spacing and repeatable layouts. Crews follow a familiar pattern rather than improvising each bay. This standardization reduces decision-making time and lowers the likelihood of errors. As workers become accustomed to the system, setup speed increases further.

Stripping Through Cleaner Disassembly Sequences

Stripping is faster because flex-slab formwork follows a structured disassembly sequence. Beams, panels, and props are removed in an orderly manner, reducing congestion and confusion. This organized approach not only saves time but also improves safety on site.

Faster Reset for the Next Bay

Once stripped, components can be reset quickly for the next slab bay. Because the beam grid is reusable and spacing remains consistent, crews can move directly into reassembly without extensive preparation. This quick reset supports shorter cycle times floor after floor.

What Makes Flex-Slab Fast and When It Is Not

Flex-slab formwork is not universally faster in every scenario. Understanding where its advantages are strongest helps set realistic expectations.

Fast When Layouts Change Often

Flex-slab systems perform best on projects where slab layouts change frequently. Irregular floor plans, varying beam depths, and dense column grids all benefit from a system that adapts without extensive rework. In these situations, the time saved on setup and adjustment outweighs any initial learning curve.

Crew Training Effect in the First Cycles

As with any system, flex-slab formwork has a learning phase. The first one or two cycles may take longer as crews become familiar with component placement and sequencing. Once this phase is complete, productivity typically increases rapidly, and cycle times stabilize at a faster pace.

Productivity Tips to Maximize Flex-Slab Cycle Speed

To fully realize the speed potential of flex-slab formwork, certain site practices are especially effective.

Pre-Assembly Zones

Establishing pre-assembly zones allows crews to prepare beam grids and prop assemblies in advance. This reduces on-slab work and shortens setup time. Pre-assembled modules can be moved into place quickly when needed.

Material Staging Paths

Clear staging paths for beams, panels, and props minimize unnecessary handling. When materials flow smoothly from storage to the slab edge and back, idle time is reduced and crews remain productive throughout the cycle.

Standard Check Points for Leveling and Safety

Defining standard checkpoints for leveling and safety inspections helps prevent rework. When crews know exactly when and where checks occur, adjustments can be made early rather than after problems escalate.

How to Decide If “Faster” Matters More Than “Cheaper”

Speed is valuable, but its importance varies by project context. Understanding when faster cycles deliver real benefits helps guide system selection.

Schedule-Driven Projects With Tight Deadlines

Projects with strict completion deadlines or penalty clauses benefit greatly from faster slab cycles. In these cases, reducing even a small amount of time per floor can significantly improve overall project performance.

Labor-Scarce Regions

In regions where skilled labor is limited or expensive, systems that reduce labor hours offer clear advantages. Flex-slab formwork supports efficient use of available crews by simplifying assembly and reducing rework.

Night Pours and Limited Access Jobsites

Sites with restricted working hours or limited access require predictable and efficient workflows. Faster setup and stripping reduce the risk of delays that could push work outside permitted time windows.

Cycle Time Map: Flex-Slab vs Traditional Slab Formwork

Slab task | Traditional method time sinks | Flex-slab advantage | Notes |

Layout and shoring | Measuring and cutting | Modular spacing | Training improves speed |

Leveling | Repeated adjustments | Adjustable heads and props | Fewer iterations |

Stripping | Many small parts | Structured disassembly | Safer workflow |

Reset next bay | Rework and repositioning | Reusable beam grid | Good staging helps |

This comparison highlights how flex-slab formwork reduces time losses across multiple stages rather than focusing on a single task.

Conclusion

Flex-slab formwork is typically faster than traditional slab formwork because it reduces repeated measuring, cutting, and unstructured stripping, especially on complex or changing floor plans. By breaking the slab cycle into clear, repeatable steps, the system supports smoother workflows and more predictable schedules. For projects using H20 Timber Beam Formwork, flex-slab solutions from Lianggong are designed to balance speed, adaptability, and durability under real site conditions. When faster cycles matter more than marginal differences in material cost, this approach offers a practical advantage. If you want to explore how a flexible slab formwork system can fit your floor layout, clear height, and schedule requirements, contact us to discuss your project and receive technical support tailored to your needs.

FAQ

Is flex-slab formwork always faster than traditional slab formwork?

Flex-slab formwork is usually faster on complex or changing layouts, while speed differences may be smaller on perfectly repetitive floors.

How long does it take for crews to adapt to flex-slab systems?

After one or two cycles, most crews become familiar with the system and achieve stable, faster cycle times.

Can flex-slab formwork handle different slab thicknesses?

Yes. Adjustable props and beam spacing allow the system to adapt to varying slab thicknesses without major reconfiguration.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe