With the vigorous development of the construction industry, as a key part of concrete pouring and molding, the selection of formwork is directly related to the quality, efficiency and cost of the project. Steel frame formwork and aluminium frame formwork are two types of formwork widely used in the construction field, each of which has unique performance characteristics and is suitable for different construction scenarios. Below, let's take a closer look at these two formwork systems to provide accurate selection references for construction practitioners in practical applications.

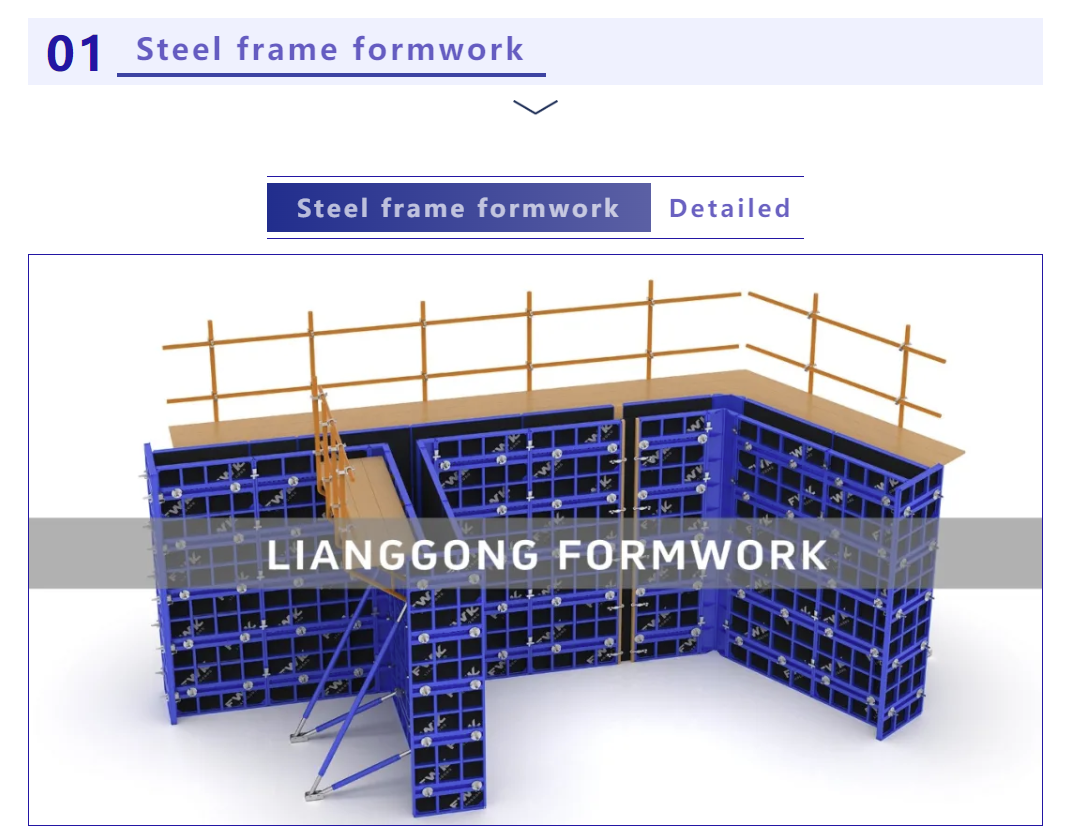

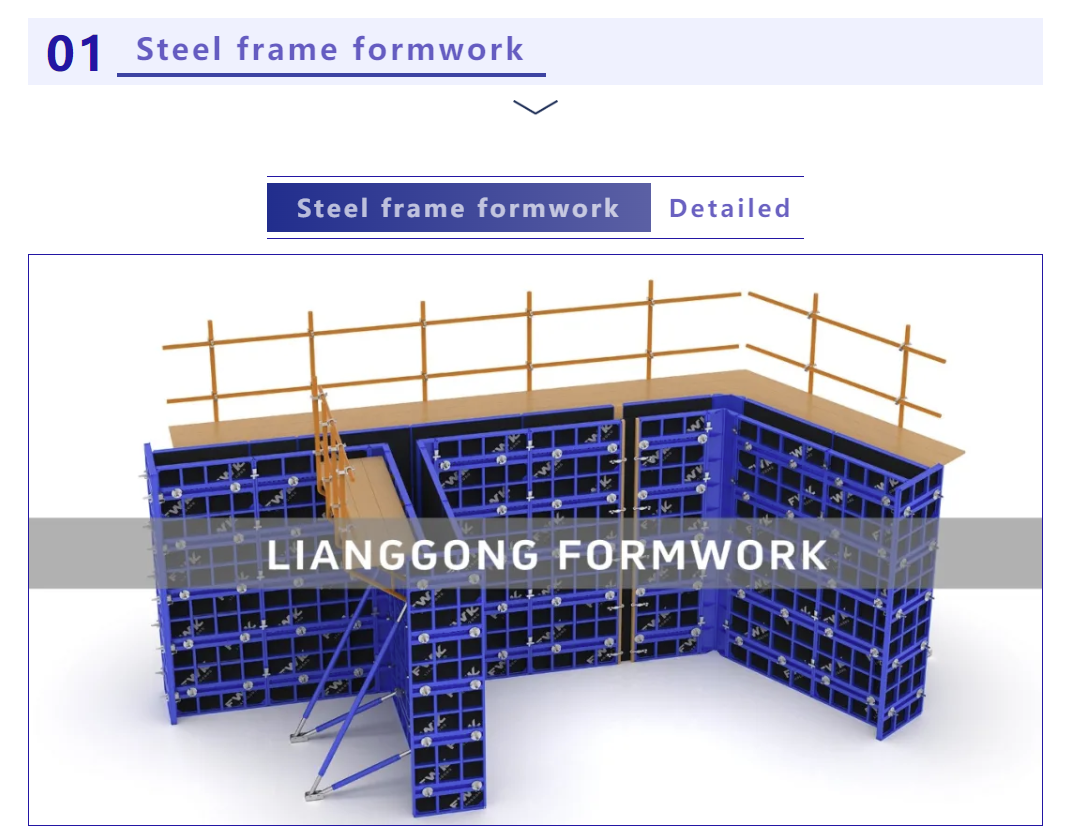

Steel Frame Formwork |

I. Material | The steel frame is made of Q355 material, with high-quality hardwood plywood as the inner lining. The surface is covered with a PP plastic film. It is lightweight, durable, and waterproof. |

II. Cost | 1. The initial procurement cost is relatively low.<br>2. More manpower and equipment are required for handling and installation, leading to an increase in labor costs and equipment usage costs.<br>3. The long-term usage cost is reduced due to the reusability of the plywood and frame. |

III. Construction Efficiency | 1. During construction, steel-framed formwork is heavier than aluminum-framed formwork. 2. Manpower and lifting equipment are required for handling, resulting in low construction efficiency. |

IV. Panel Size Range | 1. Height ranges from 600 mm to 3000 mm, and width ranges from 500 mm to 1200 mm. 2. The maximum working width of a single panel can be flexibly adjusted on-site according to the actual situation during construction. |

V. Connection Components and Their Adjusting Functions | 1. The alignment coupler is used to connect the formwork panels, providing an adjustment range of 0-150 mm to prevent grout leakage. 2. The column clamp is used for formwork panels during column construction, enabling precise adjustment of column dimensions with an accuracy of 50 mm. 3. There are various special accessories, such as those for formwork inside shafts, to meet the construction needs of complex structures. |

VI. Application | Widely used in various complex scenarios. 1. Applied in the construction of multiple building structures such as foundations, basements, retaining walls, swimming pools, shafts, tunnels, and columns. 2. Used in the construction of building-structure corners, T-shaped connection parts, and single-sided formwork (such as one-time pouring with a maximum height of 6m). |

1. High strength and high stiffness: the steel frame formwork is made of steel, which can withstand large concrete pouring pressure and construction load, and is not easy to deform, so as to ensure the dimensional accuracy and surface flatness of concrete components, and is suitable for the construction of various large-scale and high-rise building structures;

2. Good durability: The steel has high corrosion resistance and wear resistance, and the steel frame formwork can still maintain good performance and long service life after many uses. Under normal circumstances, the steel frame formwork can be reused more than 200 times, which can greatly reduce the construction cost compared with the formwork of other materials;

3. Flexible assembly: The plate size of the steel frame formwork is relatively standard, which can be flexibly combined according to different construction needs, and is suitable for the construction of various structural forms, such as columns, beams, plates, walls, etc. At the same time, its connection mode is simple, the installation and disassembly efficiency is high, and the construction period can be shortened;

4. Smooth and smooth surface: The panel of the steel frame template is generally made of cold-rolled steel plate or stainless steel plate, with high surface flatness, smooth and easy to demould. This not only makes the surface quality of the concrete good, reduces the workload of subsequent plastering and other decoration processes, but also improves the appearance quality of the concrete, and makes the surface of the component smooth and beautiful;

5. Good environmental performance: the steel frame formwork can be recycled and reused, which meets the requirements of the national environmental protection policy. After the end of the project, the formwork can be recycled and re-smelted, which reduces the generation of construction waste and reduces the pollution to the environment.

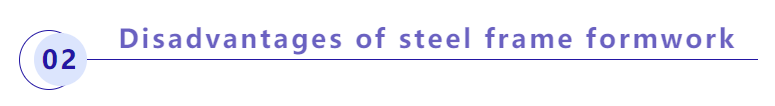

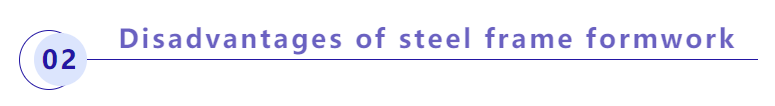

1. Self-weight: the weight of the steel frame template is large, which brings certain difficulties to the handling, installation and disassembly in the construction process, and needs to be equipped with corresponding lifting equipment, which increases the construction cost and labor intensity;

2. Easy to rust: Although the steel itself has a certain corrosion resistance, the steel frame formwork is easy to rust in a humid environment or when exposed to alkaline substances in concrete for a long time. Rust will affect the surface quality and service life of the formwork, and regular anti-rust treatment is required, which increases maintenance costs and work;

3. Poor thermal insulation performance: The thermal conductivity of steel is large, and the thermal insulation performance of steel frame formwork is not as good as that of some wooden or plastic formwork. During winter construction, additional insulation measures are required to prevent the concrete from freezing, increasing the complexity and cost of construction;

4. High noise: In the process of installing and disassembling the steel frame formwork, due to the collision and friction between the steels, large noise will be generated, which will have a certain impact on the environment around the construction site and the lives of residents. In some areas with high requirements for noise control, corresponding noise reduction measures need to be taken.

65 Steel Frame Formwork

65 Steel Frame Formwork |

Weight per square meter | 40 kg/sqm |

Plywood thickness | 12 mm |

Material | Q355 |

Panel thickness | 63.5 mm |

Maximum size | 1.2 x 3 m |

Application | Walls & Columns |

120 Steel Frame Formwork

120 Steel Frame Formwork |

Weight per square metre | 51 kg/sqm |

Plywood thickness | 18 mm |

Material | Q355 |

Panel thickness | 120 mm |

Max. size | 1.35*3.3 m |

Bearing capacity | 80 KN/SQM |

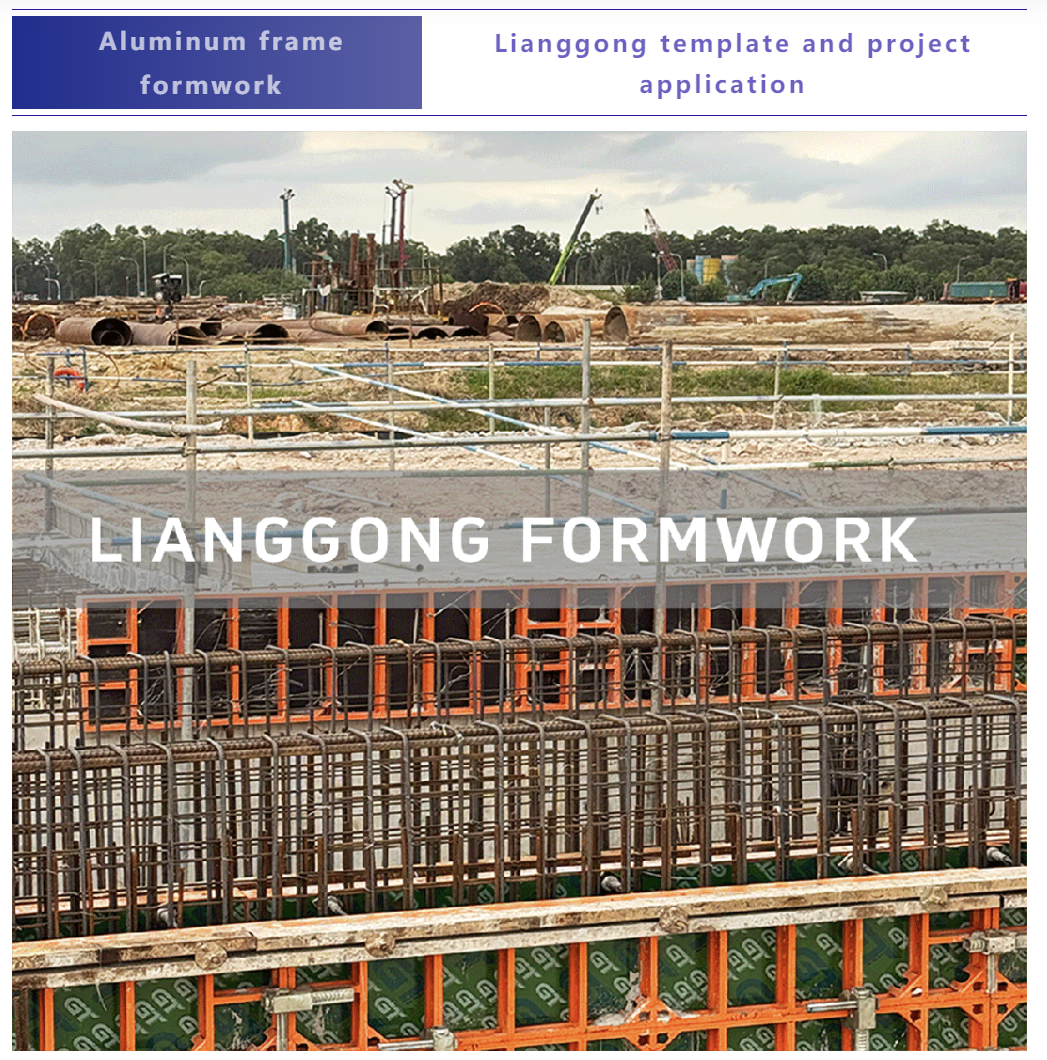

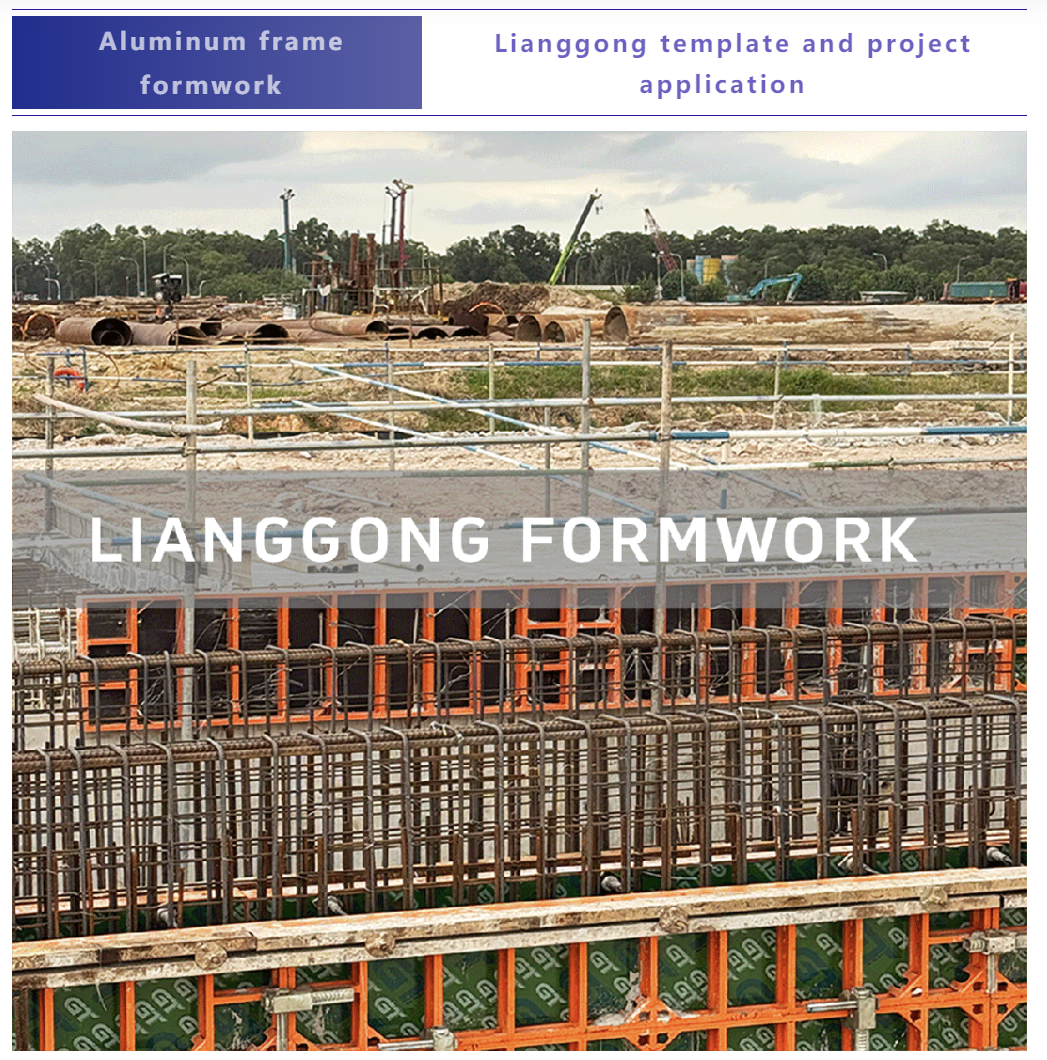

Lianggong formwork has been rooted in the field of steel frame formwork for many years, and has continuously deepened and innovated the steel frame formwork by virtue of its persistent pursuit of quality and unremitting innovation in technology. For example, the Indonesian parking lot project under construction uses our steel frame formwork system, and the construction site of the Indonesian parking lot project is close to the existing building, and the construction party needs to accurately layout it in a limited space. The rapid assembly characteristics of our steel frame formwork have been fully utilized. The construction team quickly completed the construction of the formwork, which greatly shortened the construction period. In the large-area ground pouring operation, the high strength of our steel frame formwork ensures the flatness of concrete pouring and avoids the problem of uneven ground caused by formwork deformation. At the same time, its reusability also reduces the material cost of the project.

Aluminium Frame Formwork |

Material Characteristics | Frame adopts 6061 - T6 aluminum alloy material; Lightweight and high strength. |

Cost | 1. Higher initial procurement cost. 2. Lower average use cost when there are more than 30 standard floors. 3. Reduced labor cost due to easy installation and reduced construction equipment cost as no large lifting equipment is needed. 4. Lower long - term use cost as plywood and frames can be reused. |

Construction Efficiency | 1. Flexible combination of forms by construction personnel, high construction efficiency. 2. Lightweight feature makes operation safer and more convenient, without the need for complex lifting equipment, high construction efficiency.Meets the multi - size requirements of building structures. |

Size Specifications | Panel heights include multiple options such as 75cm, 125cm, 150cm, 250cm, and 300cm.Combined with standard elements of 4 different widths (25cm, 50cm, 75cm, 100cm). |

Connecting Components and Adjustment Functions | 1. Alignment couplers secure panel connections. 2. Tie rod system enhances overall structural strength and stability. 3. Hinged corners adapt to bevel angles of 75° and above, used for connecting internal and external wall corners. 4. Diagonal braces calibrate the formwork system and position prefabricated concrete components. 5. Platform scaffolding provides a safe working and pouring platform. 6. Accessories such as large washer nuts facilitate easy installation and dismantling. |

Application Scenarios | Suitable for construction scenarios such as shear walls, elevator shafts, stairwells, initial stages of foundation engineering, and rectangular piers. |

Turnover Times | A set of aluminium frame formwork can be reused 200 - 300 times, and some plywood can be reused 40 times. |

1. Light weight: the density of aluminum is relatively small, and the weight of aluminum frame formwork is light, generally about 20 - 25kg per square meter, which is convenient for manual handling and installation, reduces labor intensity, and improves construction efficiency, especially suitable for some construction parts where the space is narrow or the lifting equipment is inconvenient to reach;

2. High reuse rate: The aluminum alloy material has good corrosion resistance and strength, and the aluminum frame template can be reused more than 200 times under normal use and maintenance conditions, which greatly reduces the cost of using the template. At the same time, due to its long service life, the frequency of formwork replacement is reduced, which is conducive to ensuring the construction progress and quality;

3.High construction efficiency: the assembly and disassembly of the aluminum frame formwork are relatively simple, and the quick-release system is adopted, which can quickly complete the support and dismantling of the formwork. Moreover, the precision of the aluminum frame formwork is high, and the splicing is tight, which can effectively reduce the slurry leakage phenomenon in the concrete pouring process, improve the concrete surface quality, reduce the workload of the subsequent repair and decoration process, thereby shorten the whole construction period;

4. Good environmental performance: the aluminum frame template can be recycled and reused, after the end of the project, the template can be recycled and re-smelted into other aluminum products, with a high recovery rate, in line with the requirements of the national environmental protection policy, reducing the pollution to the environment;

5. Better thermal insulation performance: Compared with the steel frame formwork, the thermal conductivity of aluminum alloy is lower and has certain thermal insulation performance. In some buildings that do not have particularly high insulation requirements, the use of aluminum frame formwork can reduce the transfer of heat to a certain extent, which helps to reduce the energy consumption of the building.

1. Relatively small stiffness: Although the aluminum frame formwork has a certain strength, its stiffness is relatively small compared to the steel frame formwork. When bearing large concrete pouring pressure or construction load, deformation may occur, and reasonable reinforcement and support need to be carried out in the design and use process to ensure the dimensional accuracy and surface flatness of concrete components;

2. Not resistant to high temperature: the melting point of aluminum alloy is relatively low, when encountering high temperature environment, such as fire, etc., the performance of aluminum frame template will be greatly affected, and even deformation, melting and other phenomena may occur, affecting its use safety. Therefore, it is necessary to pay attention to fire prevention measures at the construction site to avoid the formwork being damaged by high temperature;

3. Easy to wear: The surface hardness of the aluminum frame formwork is relatively low, and it is easy to be worn during use, especially in the parts that are in contact with concrete. Wear will affect the surface finish and dimensional accuracy of the formwork, and reduce the molding quality of concrete, so it is necessary to regularly inspect and maintain the formwork, and repair or replace the parts with serious wear in time;

4. High requirements for later maintenance: In order to ensure the performance and service life of the aluminum frame formwork, regular maintenance and maintenance are required. Including cleaning the surface of the formwork, oiling and preventing rust, checking the fastening of the connecting parts, etc. If it is not properly maintained, it is easy to cause problems such as rust and deformation of the formwork, which will affect its use effect.

Aluminium Frame Formwork |

Weight per square metre | 21 kg/sqm |

Plywood thickness | 18 mm |

Material | Q355 |

Panel thickness | 120 mm |

Max. size | 1.35*3.3 m |

Bearing capacity | 80 KN/SQM |

Because of its advantages of light weight and high construction efficiency, aluminum frame formwork is rapidly occupying the C position of building construction, and has received extensive attention from major construction units at home and abroad. With excellent product quality and excellent service, our company has emerged on the international stage, and its aluminum frame formwork has become the priority choice for many overseas projects, and the Singapore project is a very representative successful case. The scale of the project in Singapore is very large, and the requirements for construction quality and construction efficiency are extremely strict. From the early stage of the project, our company worked closely with the local construction team to gain an in-depth understanding of the project needs and tailor the aluminum frame formwork solution. Our aluminum frame formwork is highlighted by lightweight design, and the weight per unit area is significantly lower than that of similar products, which greatly reduces the difficulty of handling for construction personnel and improves construction efficiency. At the construction site, workers quickly complete the assembly with the help of the simple splicing system of the formwork, making the originally complex formwork construction work easy and efficient. During the whole project cycle, our company has set up a professional after-sales technical team to provide a full range of technical support for the construction party. From the on-site guidance of formwork installation to the timely solution of problems encountered in the construction process, it can achieve rapid response and efficient processing, which has won high praise from local partners.

All in all, steel frame formwork and aluminum frame formwork have their own advantages and disadvantages. When selecting the formwork, construction practitioners need to comprehensively consider the construction site conditions, building structure types, construction schedule requirements and cost budgets and other factors, so as to make the most suitable choice for the actual needs of the project, so as to achieve efficient construction and high-quality construction results.

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe