I. Project Overview

The Indonesian parking building project is of a large scale, with a single - floor area of nearly 3,000 square meters and a 10 - story above - ground parking building. Lianggong provided approximately 550 tons of formwork products for this project. A total of 21 containers were selected to complete the delivery via sea transportation. The formwork used in this project covers the Drophead System and Flex - table Formwork Syestem in the horizontal system, as well as the 65 Steel Fram formwork for wall and column and all - steel cylindrical formwork in the vertical wall and column system. Each type of formwork plays a crucial role in the construction of the parking building.

II. Transportation Detail

1. What Transportation Method is Adopted?

We adopt sea transportation. The operation team of Lianggong closely monitors the production progress. Once there is an opportunity for delivery, they immediately contact freight forwarders in advance. During this process, they carefully consider various factors such as transportation costs, transit times, and port conditions. For example, if the selected port is often congested, the transportation time will definitely be extended, and the cost may also increase. Therefore, a transportation route must be carefully planned to find the most suitable solution.

2. How is the Transportation Plan Developed?

Developing a transportation plan is a technical task that requires professional technicians. They will formulate a packing plan based on the volume, quantity, and characteristics of the products. Take these formworks as an example; some are large in volume, and some are heavy in weight. They need to be arranged reasonably in the containers. Technicians will repeatedly optimize to select the most appropriate container models and determine the accurate quantity. After the preliminary plan is completed, it cannot be implemented immediately. It must be sent to the customer for review. Only when the customer approves can this packing plan officially take effect.

3. What Types of Containers are Used?

We have put a lot of thought into the selection of containers. Since this is a large - batch order, 18 40 - foot dry containers are used. The internal dimensions of this type of container are approximately 12.03m×2.35m×2.39m, with a volume of about 67 cubic meters, which is especially suitable for transporting large - quantity goods. In addition, there are 2 20 - foot dry containers, with internal dimensions of approximately 5.9m×2.35m×2.39m and a volume of about 33 cubic meters, mainly used to load small - to - medium - batch goods. There is also 1 40 - foot open - top container, which is used for goods that are not convenient to load and unload with a forklift. The top of this container can be opened, facilitating the handling of special - shaped goods.

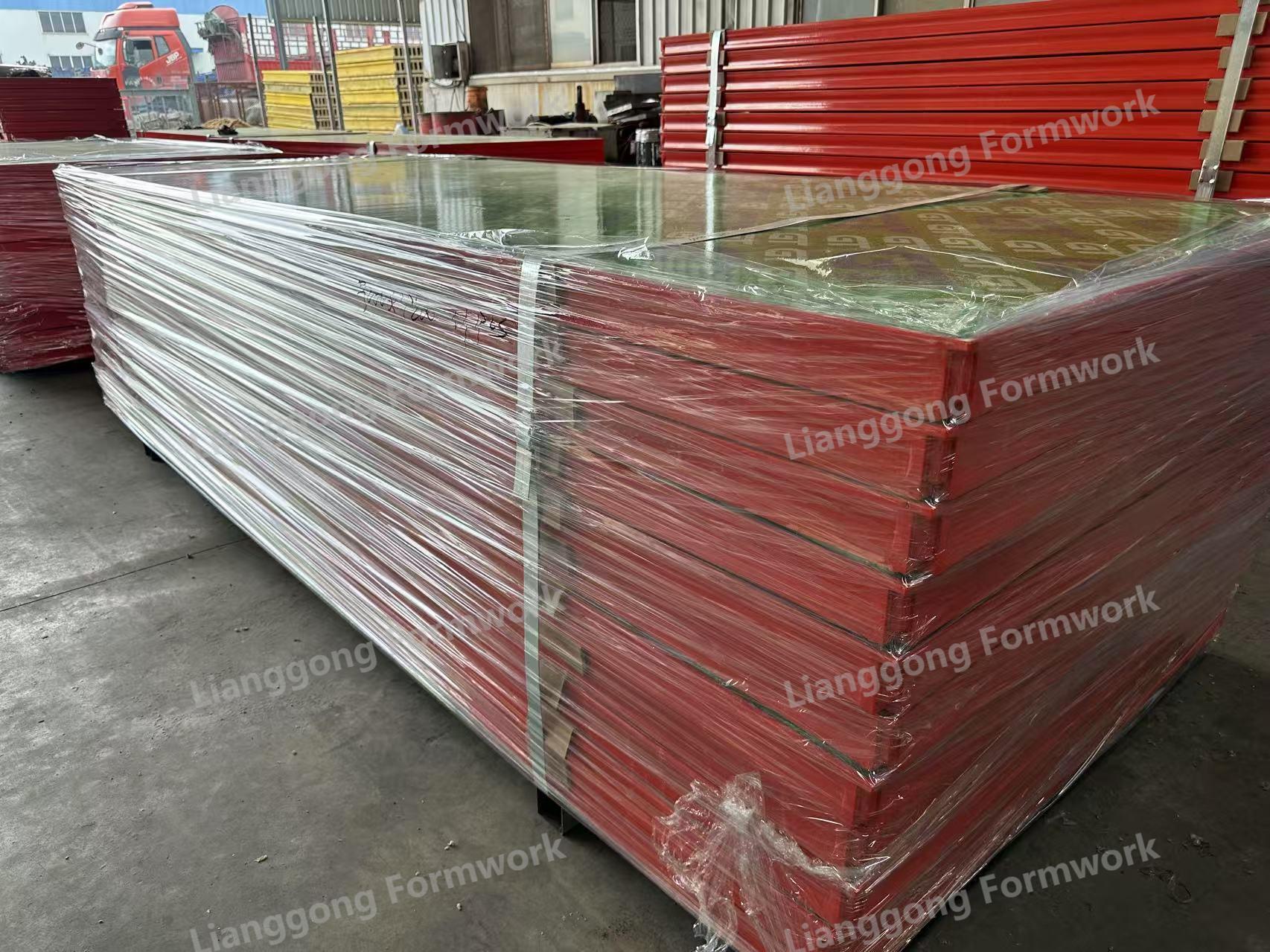

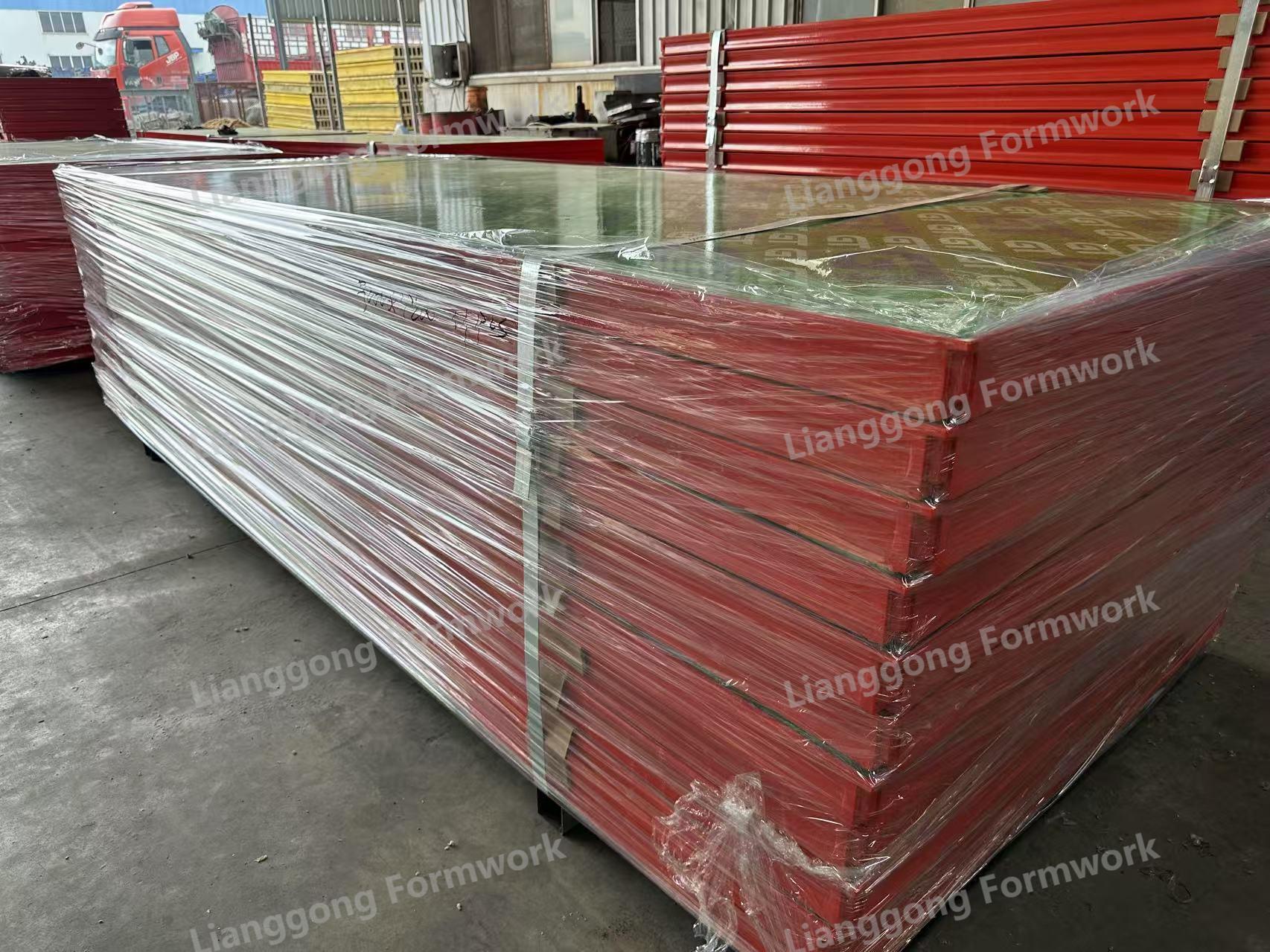

4. Is the Cargo Packaging Reasonable?

Cargo packaging is of vital importance. For single - piece formworks, we tightly wrap them with stretch film to effectively prevent moisture and scratches during transportation. For bulk shipments, we use iron pallets to stack the formworks neatly and then reinforce them with steel straps. There is a lot of knowledge in this. The size of the pallets is precisely designed according to the internal dimensions of the containers, which can not only maximize the use of space but also prevent the formworks from shaking inside the containers. For parts and some accessories, we usually choose to package them with ton bags or iron frames to ensure their safety during transportation.

5. Is the Container Loading Capacity Maximized?

Of course, we aim to maximize the container loading capacity! We follow the principle of "heavy on the bottom, light on the top; large on the bottom, small on the top" and plan the stowage in advance. First, place the heavier and larger - sized formworks at the bottom of the container to ensure a stable center of gravity and safer transportation. Then, we reasonably match different specifications of formworks. For example, stack standard - sized rectangular formworks with special - shaped formworks and use the corner spaces of the special - shaped formworks to place small - sized accessories. Through such precise calculations and simulations, we can increase the container loading capacity by 10% - 15%, greatly saving transportation costs.

6. Will We Assist the Consignee in Customs Clearance?

Lianggong has a professional operation team and will never slack off in customs clearance. We will prepare accurate invoices, packing lists, bills of lading, and other documents in advance and communicate with the consignee in advance. Once the consignee needs customs clearance assistance, we can promptly provide copies of the necessary customs clearance documents. If there are any questions from the customs, we can also help answer them to ensure the smooth progress of the customs clearance process.

7. How is the Sea Transportation Risk Assessed?

There are indeed many risks in sea transportation. Severe weather, such as typhoons and huge waves, may cause container displacement and damage; port congestion may lead to shipping schedule delays. To address these risks, we closely monitor the weather forecast before shipment and arrange the shipment time reasonably to avoid periods when severe weather is frequent. When choosing a shipping company, we also carefully select those with good reputations and stable shipping schedules. Moreover, we will purchase sufficient cargo insurance according to the customer's needs, so that even if there are actual losses, there will be certain protection.

III. Conclusion

From the selection of transportation methods, the development of transportation plans, to cargo packaging, container stowage, and finally customs clearance assistance and risk assessment, Lianggong has achieved meticulous planning and professional operation in every link. It is precisely because of this that we have ensured the efficient and safe transportation of the Indonesian parking lot order cargo to the destination, contributing to the smooth construction of the Indonesian parking building project. The next time we encounter a similar transportation task, we are confident that we can do even better!

Filipino

Bahasa Indonesia

한국어

Tiếng Việt

English

العربية

Français

Русский

Español

Português

Bahasa Melayu

Deutsch

italiano

日本語

Nederlands

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

ဗမာစာ

தமிழ்

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

latviešu

অসমীয়া

Беларуская мова

Български

डोग्रिड ने दी

Esperanto

Eʋegbe

íslenska

Türkmençe